Günter Papenburg Ag

Mansfelder Straße WEST geht in nächste Phase über15.04.2024

Die Baustelle in der Mansfelder Straße mit der Elisabethbrücke geht in die nächste Phase über! In den vergangenen Wochen wurden neue Bauweichen eingebaut, um die nächsten Baufelder zu bearbeiten. Wir sind stolz darauf, dass der erste Teil des Gleisneubaus abgeschlossen ist und die Straßenbahn nun über die neuen nördlichen Gleise fahren kann.

Mansfelder Straße WEST geht in nächste Phase über

Die Baustelle in der Mansfelder Straße geht in die nächste Phase über! In den vergangenen Wochen wurden neue Bauweichen eingebaut, um die nächsten Baufelder zu bearbeiten. Wir sind stolz darauf, dass der erste Teil des Gleisneubaus abgeschlossen ist und die Straßenbahn nun über die neuen nördlichen Gleise fahren kann. Doch ruhen wir nicht, denn jetzt beginnen die Arbeiten am südlichen Gleis zwischen der Hafenstraße und Saline.

Auch westlich der Elisabethbrücke machen wir Fortschritte: Die notwendigen Leitungstiefbauarbeiten sind größtenteils abgeschlossen, und im April starten die Arbeiten an der zukünftigen Gleisanlage. Das Ziel ist es, die Mansfelder Straße zwischen Saline und Hafenstraße bis zu den Sommerferien fertigzustellen. Wir wissen, dass diese Baumaßnahmen eine Herausforderung für die Anwohner und Verkehrsteilnehmer darstellen, und wir danken allen für ihr Verständnis und ihre Geduld.

Gemeinsam bauen wir die Zukunft der Mobilität in Halle!

Baustellentagebuch der HAVAG

Mansfelder Straße WEST geht in nächste Phase über

Mansfelder Straße WEST geht in nächste Phase über

Mansfelder Straße WEST geht in nächste Phase über

Mansfelder Straße WEST geht in nächste Phase über

IFAT 2024 - Weltweit führende Messe für Kreislaufwirtschaft11.04.2024

Die IFAT Munich ist die wichtigste Plattform für Umwelttechnologien und nachhaltige Gestaltung unserer Zukunft. Sie bietet vom 13. bis 17. Mai 2024 innovative Ideen und zukunftsweisende Lösungen für industrielle und kommunale Herausforderungen. Lernen Sie an unserem Messestand auch unser kompetentes Netzwerk und unsere Partnerunternehmen kennen.

IFAT 2024 - Weltweit führende Messe für Kreislaufwirtschaft

Die IFAT, die weltweit führende Messe für Kreislaufwirtschaft, steht vor der Tür! Sie ist die wichtigste Plattform für Umwelttechnologien und nachhaltige Gestaltung unserer Zukunft.

Die bietet vom 13. bis 17. Mai 2024 innovative Ideen und zukunftsweisende Lösungen für industrielle und kommunale Herausforderungen. Lernen Sie an unserem Messestand (Halle A6/Stand 308) auch unser kompetentes Netzwerk und unsere Partnerunternehmen kennen.

Halten Sie sich den Termin frei und besuchen Sie uns auf der IFAT in München. Wir freuen uns auf Ihren Besuch mit spannenden Einblicken und inspirierenden Gesprächen.

GP Papenburg Entsorgung Ost GmbH

Die GP Günter Papenburg AG mit ihren aktuell 60 Tochtergesellschaften und Betriebsteilen verdankt ihre Stärke und Resilienz einem über Jahrzehnte perfektionierten Stoffstrommanagement. Es macht unsere verbundenen Unternehmen zu einem effizienten und leistungsstarken Kompetenznetzwerk rund um den Bau, das unseren Kunden und Auftraggebern nachhaltige Lösungen und Produkte bietet.

Circular Economy spielt für uns seit jeher eine zentrale Rolle, um Rohstoffe ressourcenschonend und Recyclingmaterial technologisch sinnvoll einzusetzen.

Lernen Sie auf unserem Gemeinschaftsstand auch unsere Beteiligungsgesellschaften der Sparte kennen.

NORIS Entsorgung GmbH

„Wir Entsorgen ohne Sorgen“, das ist unser Motto und unsere Leidenschaft. Die ist Teil eines effizienten und leistungsstarken Kompetenznetzwerkes innerhalb und außerhalb der GP Günter Papenburg Unternehmensgruppe. Wir bieten rund um den Bau für unsere Auftraggeber stets ökologisch sinnvolle und nachhaltige, wie auch ökonomisch interessante Lösungen und Produkte an.

Electrocycling GmbH

Die Expertise von beruht auf 30-jähriger Betriebserfahrung und der Verarbeitung von mehr als einer Millionen Tonnen an Elektroaltgeräten. Wir haben von Beginn an Maßstäbe gesetzt beim Einsatz und bei der stetigen Weiterentwicklung von innovativen, hochwertigen Verwertungstechniken zur Rohstoffgewinnung. Wir freuen uns darauf, Ihnen unser umfassendes Dienstleistungsangebot, beginnend bei der Beratung zu geeigneten Erfassungs-, Transport- und Entsorgungsszenarien, bis hin zur optimalen Verwertung zu erläutern.

FRIEDRICH Gruppe

Die hat sich in den letzten 70 Jahren als führendes und dynamisches Dienstleistungsunternehmen in der Eisen- und Stahlindustrie etabliert. Insbesondere die vollständige Wiederaufbereitung der im Stahlproduktionsprozess anfallenden Reststoffe und deren Rückführung in die Kreislaufwirtschaft ist eine der Zukunftsstrategien von Friedrich. In enger Zusammenarbeit mit unseren Kunden streben wir nach innovativen Lösungen hin zu einer klimaneutralen Produktion. Circular Economy und die nachhaltige Schonung unserer Umwelt ist eine unserer größten Motivationen.

GFR mbH

Für leichte Bauprodukte wie Gipsplatten und Glaswolle bietet die spezielle Recyclinglösungen an, um diese wichtigen Ressourcen wieder in den Stoffkreislauf zurückzuführen. Unsere Kompetenz basiert auf dem Know-how unserer Gesellschafter, der GP Gruppe als Anwender und der Knauf Gruppe als Hersteller dieser Produkte. Zudem sind wir seit über 35 Jahren fest im Bereich der Kraftwerksver- und -entsorgung etabliert. Gerne stehen wir Ihnen für Fragen zur Ver- und Entsorgung von Kohle-, Biomasse-, Klärschlammkraftwerken sowie anderer Kraftwerksarten zur Verfügung.

DAS ITEL - DEUTSCHES LITHIUMINSTITUT GMBH

Lithium ist nicht nur bedeutender Grundstoff für nachhaltige Mobilität und eine erfolgreiche Energiewende. Die Technologie zur Lithiumkonversion ermöglicht zudem die Nutzung der Nebenprodukte Gips und Aluminiumsilikate als wichtige Grundstoffe in der modernen Mineral- und Bauwirtschaft. Mit seiner Forschung unterstützt das so die Kreislaufführung und das Zero-Waste-Konzept der modernen Wirtschaft.

IFAT 2024 - Weltweit führende Messe für Kreislaufwirtschaft

GP Digitaltag: Ein voller Erfolg!15.04.2024

Wow, was für ein Tag! Am 09. März 2024 fand unser 1. GP Digitaltag statt und es war ein voller Erfolg für Groß und Klein.

GP Digitaltag: Ein voller Erfolg!

Wow, was für ein Tag! Am 09. März 2024 fand unser 1. GP Digitaltag statt und es war ein voller Erfolg für Groß und Klein.

Zahlreiche Mitarbeiterinnen und Mitarbeiter, Auszubildende und Familienangehörige kamen nach Halle-Ammendorf, um sich über die digitale Transformation in unserem Unternehmen zu informieren und spannende Einblicke in aktuelle Projekte zu erhalten. Denn die Digitalisierung von vielen Prozessen in operativen und kaufmännischen Bereichen, die Nutzung von digitalen Systemen, Sensoren und KI verändern täglich Arbeitsplätze und Tätigkeiten überall bei uns im Unternehmen. Die Teilnahme am GP Digitaltag war für die Mitarbeitenden auch online über mehrere YouTube-Streams möglich.

Ein aufregender Tag mit tollen, spannenden Einblicken und interessanten Gesprächen. Neben Vorträgen und Workshops war es großartig zu sehen, wie wir gemeinsam die Chancen und Herausforderungen der Digitalisierung diskutiert haben. Wir hoffen, dass viele neue Erkenntnisse und Inspirationen mitgenommen werden konnten und man sich noch motivierter fühlt, die Zukunft des Unternehmens aktiv mitzugestalten.

Wir bedanken uns bei allen Teilnehmerinnen und Teilnehmern für ihr großes Interesse und freuen uns schon auf den nächsten GP Digitaltag! Bleibt neugierig und aufgeschlossen für die Veränderungen, die vor uns liegen.

Alle Highlights des

1. GP DIGITALTAGs

finden Sie in unserem ausführlichen Video auf

GP Digitaltag: Ein voller Erfolg!

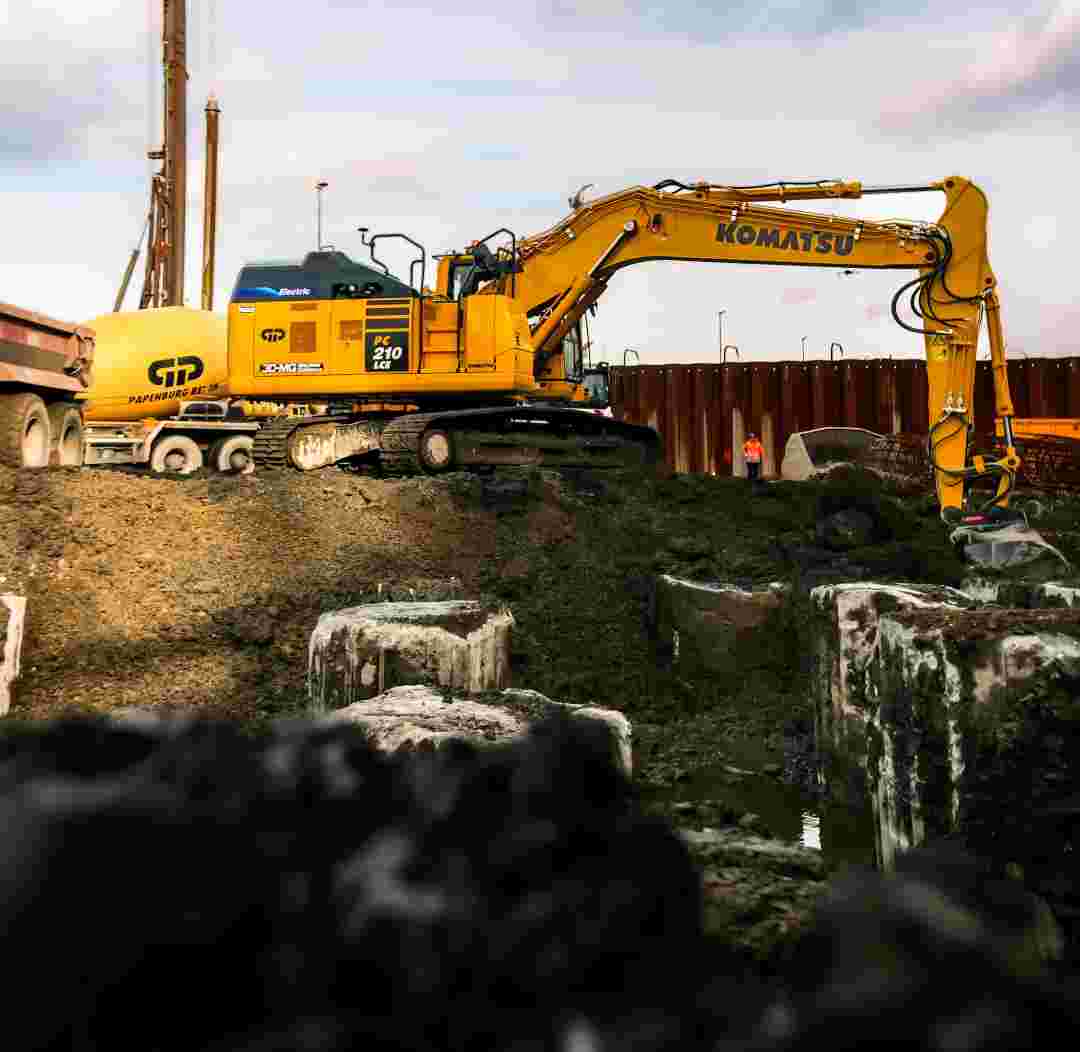

Auf dem Weg zur Nachhaltigkeit: Elektrifizierung und Tests mit dem Komatsu PC210 LCE20.03.2024

Die GP Papenburg Maschinentechnik treibt aktiv die Elektrifizierung von Baustellen voran und führt bahnbrechende Tests mit dem Komatsu PC210 LCE durch.

Auf dem Weg zur Nachhaltigkeit: Elektrifizierung und Tests mit dem Komatsu PC210 LCE

Die GP Papenburg Maschinentechnik treibt aktiv die Elektrifizierung von Baustellen voran und führt bahnbrechende Tests mit dem Komatsu PC210 LCE durch. Der vollelektrische Bagger verfügt über ein Arbeitsgewicht von 21 Tonnen und einer Batteriekapazität von über 450 kWh. Der Einsatz dieses Baggers markiert einen Meilenstein, da er seinen ersten Baustelleneinsatz in Deutschland bei uns absolviert und zu den vier einzigen Maschinen dieses Typs gehört, die in Europa getestet werden.

Die Leistungsfähigkeit des Elektrobaggers sowie die umgebenden Einsatzbedingungen stehen im Mittelpunkt unserer Tests. Wir analysieren nicht nur die Leistung im täglichen Betrieb, sondern betrachten auch kritisch Fragen zur Stromversorgung, Ladeinfrastruktur, Stromverbrauch, technischen Infrastruktur, Störungsbehandlung, rechtlichen Aspekten und Kosten-Nutzen-Analyse. Diese Untersuchungen sind essenziell für die Bewertung der Eignung elektrischer Baumaschinen für zukünftige Bauvorhaben und tragen maßgeblich dazu bei, die Nachhaltigkeit unserer Branche voranzutreiben.

Auf dem Weg zur Nachhaltigkeit: Elektrifizierung und Tests mit dem Komatsu PC210 LCE

Verantwortung leben – Integrität sichern08.04.2024

Die GP Gruppe hat sich zu integrem und verantwortungsvollem Handeln verpflichtet. Unser Hinweisgebersystem bietet unseren Mitarbeitern, Kunden und Geschäftspartnern eine sichere Plattform, um mögliche Verstöße gegen unsere Grundsätze zu melden. Erfahren Sie mehr über unser Engagement für Integrität und Compliance in unserer Grundsatzerklärung.

Verantwortung leben – Integrität sichern

Unsere Verpflichtung für Mensch und Umwelt

Die GP Günter Papenburg AG bekennt sich zu einem nachhaltigen und verantwortungsvollen Handeln, das Mensch und Umwelt in den Mittelpunkt stellt.

Wir sind ein in der Baubranche tätiges Familienunternehmen. Das Kompetenznetzwerk aus 60 Tochtergesellschaften und Betriebsteilen beschäftigt bundesweit rund 4.000 Mitarbeiter:innen in den Bereichen Rohstoffgewinnung, Produktion von Baustoffen, Hoch-, Tief-, Straßen- und Gleisbau sowie Maschinen- und Anlagenbau, Logistik, Recycling und Verwertung. Das breite Leistungsspektrum der GP Gruppe deckt die komplette Wertschöpfungskette des Bauens ab.

Bei der GP Gruppe ist Integrität ein grundlegendes Prinzip. Wir setzen auf Transparenz und Offenheit, um sicherzustellen, dass unsere Werte gelebt werden. Wir setzen uns für faire Arbeitsbedingungen, den Schutz der Umwelt und die Förderung des Gemeinwohls ein. Erfahren Sie mehr über unsere Werte und unser Engagement in unserer

Grundsatzerklärung der GP Günter Papenburg AG | Stand: 02.2024

Wir verpflichten uns, diese Grundsätze in allen unseren Geschäftsbereichen und Tochtergesellschaften umzusetzen. Wir messen unsere Fortschritte regelmäßig und berichten transparent über unsere Aktivitäten.

Mit Ihrer Unterstützung können wir unseren Beitrag zu einer nachhaltigen Zukunft leisten.

Hinweisgebersystem: Verantwortung leben – Integrität sichern

Die GP Günter Papenburg AG ist ein Unternehmen, das sich zu integrem und verantwortungsvollem Handeln verpflichtet hat.

Ein wesentliches Element unserer Compliance Strategie ist die Einrichtung eines webbasierten Systems für Hinweise, Beschwerden und Verbesserungsvorschläge -

Mit unserem Hinweisgebersystem bieten wir allen Mitarbeitern, Kunden und Geschäftspartnern die Möglichkeit, anonym und vertraulich auf potenzielle Verstöße gegen unsere Verhaltensregeln, Gesetze oder internen Richtlinien hinzuweisen. Wir nehmen alle Hinweise ernst und gehen ihnen sorgfältig nach.

Mit Ihrer Mithilfe können wir sicherstellen, dass die GP Günter Papenburg AG ein Unternehmen bleibt, das auf ein verantwortungsvolles Miteinander setzt.

Verantwortung leben – Integrität sichern

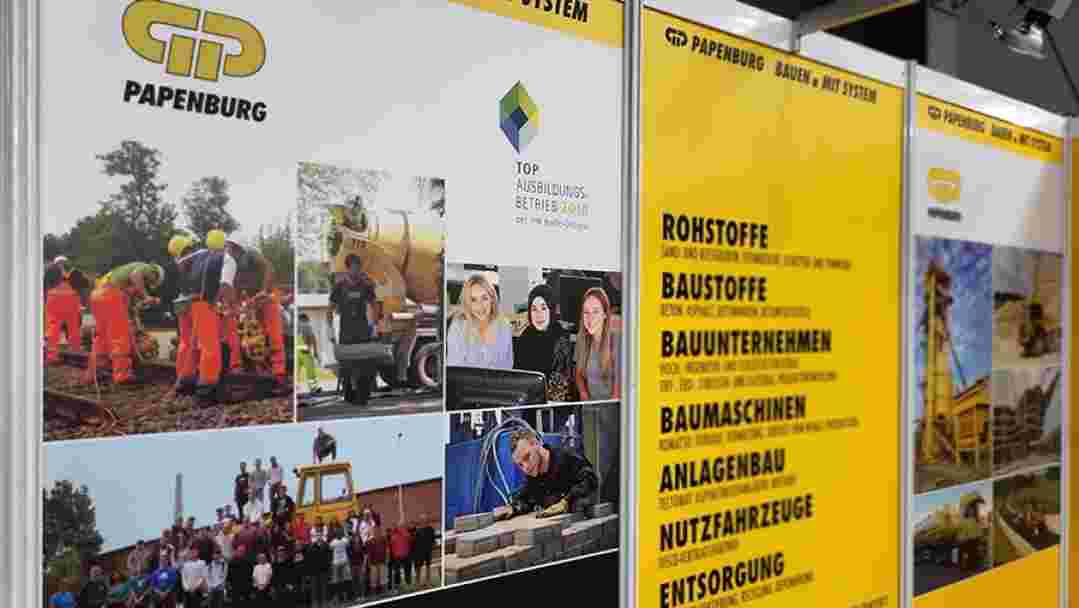

Bauen. Mit System03.04.2024

Das 1963 als Einzelunternehmung gegründete Familienunternehmen besteht heute aus einem Kompetenznetzwerk von 60 Tochtergesellschaften und Betriebsteilen der GP Günter Papenburg AG.

Bauen. Mit System

Das 1963 als Einzelunternehmung gegründete Familienunternehmen besteht heute aus einem Kompetenznetzwerk von 60 Tochtergesellschaften und Betriebsteilen der GP Günter Papenburg AG.

Wir sind breit aufgestellt und stolz darauf.

Bundesweit arbeiten rund 4.000 Mitarbeiter:innen in den Sparten Gewinnung von Rohstoffen, Produktion von Baustoffen, Hoch-, Tief-, Straßen- und Gleisbau sowie Maschinen- und Anlagenbau, Logistik, Recycling und Verwertung.

Allein im Raum Mitteldeutschland sind rund 1.500 Mitarbeiterinnen und Mitarbeiter beschäftigt. Das Unternehmen bildet in Sachsen-Anhalt derzeit 146 Auszubildende in kaufmännischen und gewerblichen Berufen aus, um den Bedarf an Fachkräften auch zukünftig decken zu können.

Als Verantwortungspartner für die Region Halle sind uns und die Unterstützung von besonders wichtig.

Unsere GP-Sparten

Was als kleine Einzelunternehmung mit großer Ambition begann, besteht heute aus einem komplexen Unternehmens-Netzwerk.

Weitblick, Mut und Anpassungsfähigkeit bringen seit Jahrzehnten Wachstum, welches das familiengeführte Unternehmen als feste Größe in der deutschen Bauwirtschaft verankert hat.

Familienunternehmen ist für uns mehr als nur ein Begriff - es ist der Auftrag füreinander einzustehen und alle Kräfte zu bündeln, um unsere Ziele zu erreichen und miteinander zu wachsen.

Konkurrenzfähig und krisensicher

Diesen Eigenschaften verdankt die GP Gruppe ihren festen Stand in der deutschen Baubranche. Unsere Stabilität erreichen wir durch ein kluges Geflecht aus verbundenen Unternehmen - von der Rohstoffgewinnung und -weiterverarbeitung über die hauseigene Logistik bis hin zum Baustoffrecycling entlang der gesamten Wertschöpfungskette der Bauindustrie produzieren.

Wirtschaftsinitiative für Mitteldeutschland

Seit der Gründung ist die GP Günter Papenburg AG Mitglied im (ehemals Wirtschaftsinitiative für Mitteldeutschland) und mit Klaus Papenburg zunächst im Kuratorium und seit März 2018 im Aufsichtsrat vertreten.

Bauen. Mit System

Wie alles begann ..03.07.2023

Alles begann mit einem gebrauchten Krupp-Laster und einer Hanomag-Planierraupe: 1963 gründete Günter Papenburg ein Ein-Mann-Fuhrunternehmen und legte damit den Grundstein für die heutige GP Günter Papenburg AG.

Wie alles begann ..

Krupp LKW mit Hanomag-Planierraupe

Krupp LKW mit Hanomag-PlanierraupeAlles begann mit einem gebrauchten Krupp-Laster und einer Hanomag-Planierraupe: 1963 gründete Günter Papenburg ein Ein-Mann-Fuhrunternehmen und legte damit den Grundstein für die heutige GP Günter Papenburg AG. Zuvor im Betrieb seines Vaters tätig, strebte der damals 24-Jährige nach etwas Eigenem. Ihm wurde schnell klar: Er will mehr als transportieren. So kaufte er 1976 die erste Kiesgrube und baute selbst Rohstoffe ab.

Ein Jahr später stieg Papenburg in den Tiefbau ein. Mit dem Unternehmen wuchsen auch die Projekte. Der Straßenbau wurde zur Erfolgsstory, die Farbe Gelb eroberte die Autobahnen. Das Erfolgsrezept: Bauen mit eigenen Rohstoffen und eigenen Maschinen.

Vieles hat sich im Laufe der Jahre verändert, immer wieder betrat man Neuland. Eines ist in der ganzen Zeit gleichgeblieben: Die Grundsätze der von Günter Papenburg gelebten Firmenphilosophie bilden damals wie heute die Handlungsbasis der Unternehmensgruppe.

Über die Jahrzehnte bewies Günter Papenburg nicht nur Unternehmergeist, sondern auch immer wieder zukunftsorientiertes Denken und großes Herz: Als 1984 der Maschinenbauer Hanomag Konkurs anmeldete und hunderten Mitarbeitenden die Arbeitslosigkeit drohte, erkannte der Unternehmer das Potential des Unternehmens und traf eine revolutionäre Entscheidung. Er investierte in Hanomag, fand zwei gleichberechtigte Investoren und schaffte es innerhalb weniger Jahre, ein totgesagtes Unternehmen wieder rentabel zu machen. Und zwar so sehr, dass der Weltkonzern Komatsu später die Hanomag übernahm.

Nach dem Mauerfall investierte Günter Papenburg auch in den Osten. Das Unternehmen half dabei, Wirtschaftsbetriebe und Industrieanlagen wieder wettbewerbsfähig zu machen und damit Arbeitsplätze zu schaffen. Halle (Saale) wurde zum zweiten Hauptsitz des Unternehmens. Papenburg ist mit der Stadt verbunden – auch in schlechten Zeiten: Als 2013 die Jahrhundertflut die Saalestadt traf, kämpfte Günter Papenburg gemeinsam mit den Helfenden gegen das Hochwasser.

Noch heute ist die GP AG ein Familienunternehmen. Während in der Geschäftsleitung längst die drei Kinder des Firmengründers agieren, steht an der Spitze der GP Gruppe noch immer Günter Papenburg selbst. Der Senior bleibt Instanz für wichtige Entscheidungen und ist in vielen Bereichen engagiert. So zeigt sich unternehmerisches Selbstverständnis und gesellschaftliche Verantwortung.

Wie schaffen wir es, konkurrenzfähig in die Zukunft zu gehen?

In der GP Günter Papenburg AG ruhen wir uns nicht auf dem aus, was wir bereits erreicht haben. Gerade als Unternehmen gilt es, sich den Herausforderungen von Morgen zu stellen.

Mithilfe modernster Technik gelingt es uns, Verfahren effizienter zu machen und weniger invasiv in die Natur einzugreifen. Wir schonen Ressourcen und Umwelt, indem wir Baustoffe recyceln – denn wir sind uns bewusst, dass für den Bau benötigte Rohstoffe endlich sind.

Mithilfe von digitalen Anwendungen gestalten wir unsere Logistik effizierter, vermeiden Leerfahrten und senken so unsere Emissionen. Denn uns liegt es am Herzen, den Wert der Natur für künftige Generationen zu erhalten.

Günter Papenburg - Bauma 2022 - HBM E-Grader (BG110M-E)

Günter Papenburg - Bauma 2022 - HBM E-Grader (BG110M-E)

Wir investieren in die Forschung - so auch zu alternativen Antrieben und Kraftstoffen, zu effizienteren Verfahren und neuen Technologien.

Perspektivisch wollen wir unsere Werke dekarbonisieren, also Kohle einsparen, auf Alternativen setzen und damit Emissionen verringern, um zukunftsfähig zu bleiben und einen Beitrag für den Umweltschutz zu leisten.

Bauen ist ein energieintensives Unterfangen. Deshalb planen wir, unseren Energiebedarf durch Nutzung von Solarenergie und Windkraft an unseren firmeneigenen Standorten selbst zu produzieren.

Die Günter Papenburg AG ist bereit für die Zukunft und bleibt bereit, neue Wege zu gehen.

Nicht zuletzt setzen wir auf unsere Mitarbeitenden, die wir gezielt aus- und weiterbilden, auf die Herausforderungen im Berufsalltag vorbereiten sowie bei der Bewältigung aktiv unterstützen und begleiten. Insbesondere Familien und jungen Menschen bieten wir eine Perspektive für die Zukunft.

Wie alles begann ..

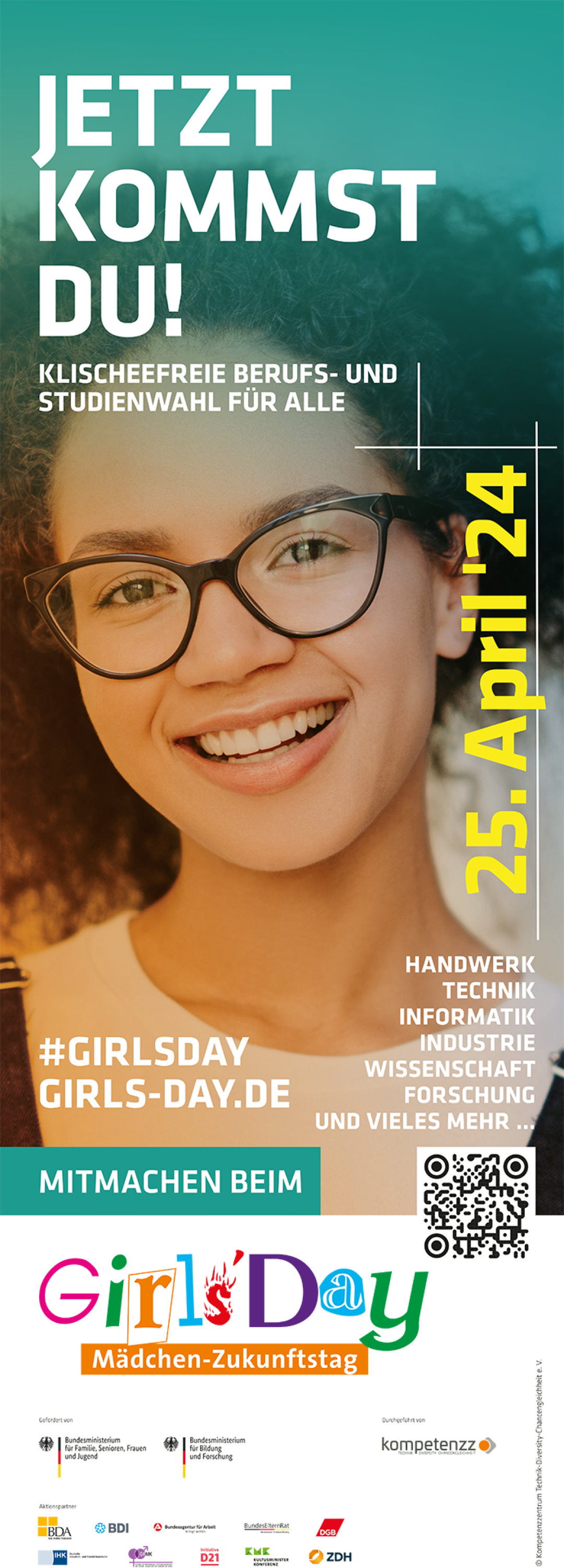

Girls'Day macht MINT für Mädchen interessant04.04.2024

Save the Date - am 25. April 2024 ist es wieder so weit und die GP Gruppe lädt zum "Girl'sDay" ein. Der jährliche Girls'Day – Mädchen-Zukunftstag bietet praktische Einblicke in technische und naturwissenschaftliche Berufe.

Girls'Day macht MINT für Mädchen interessant

Nach wie vor gilt: Mädchen und junge Frauen in Deutschland schöpfen ihre Berufsmöglichkeiten und damit ihre Zukunftschancen nicht voll aus. Auch mit guten bis sehr guten Schulabschlüssen entscheiden sich Mädchen noch immer häufig für Berufe oder Studienfächer, in denen Frauen bereits überrepräsentiert sind.

Der jährliche Girls'Day – Mädchen-Zukunftstag bietet daher praktische Einblicke in technische und naturwissenschaftliche Berufe, soll den Anteil der Mädchen und Frauen in diesen Bereichen stärken und fördern und zukunftsträchtige Berufsfelder für sie erschließen.

Seit vielen Jahren nimmt die GP Gruppe schon am Girls'- und Boys'Day teil, bei dem Mädchen und Jungen der Klassenstufen 5 bis 10 einen Tag lang die Berufswelt erleben können. Die Schüler:innen besichtigen unser Betriebsgelände in Halle-Ammendorf. Neben dem Besuch unseres Asphaltmischwerkes erfahren die Schüler:innen Wissenswertes über das Arbeitsumfeld und die täglichen Aufgaben von unseren Auszubildenden und Mitarbeitenden aus verschiedenen Sparten.

Unsere Mitarbeiter:innen stellen alle Ausbildung- und Studienmöglichkeiten vor und stehen für Fragen zur vielfältigen Berufspalette rund um den Bau zur Verfügung.

Zukunftstag - 25.04.2024

Wir freuen uns auf Dich!

Interesse geweckt?

Dann melde Dich bis zum 19.04.2024 an: (eveeno.com). Solltest Du Fragen zum Zukunftstag bei der GP Gruppe haben, beantworten unsere Mitarbeiter:innen diese gern.

Ausbildung | Bau- und Verwaltungsgesellschaft mbH

Berliner Straße 239

06112 Halle (Saale)

FON +49 345 5113-417

E-MAIL

So lief der (digitale) Girl'sDay 2021

Girls'Day macht MINT für Mädchen interessant

Papenburg

GP Günter Papenburg AG - BT Halle (Saale)

Berliner Straße 239

DE-06112 Halle (Saale)

GP Günter Papenburg AG - BT Halle (Saale)

GFK-Brücken: Nachhaltig und zukunftsorientiert14.03.2024

GP Hoch- und Ingenieurbau GmbH - Ihr Partner für zukunftsweisende Bauvorhaben. Als innovativer Brückenbauer realisieren wir individuelle GFK-Brücken (Glasfaserverstärkter Kunststoff) für höchste Ansprüche. GFK-Brücken bieten eine innovative und nachhaltige Alternative zu herkömmlichen Brückenbauweisen aus Stahl oder Beton.

GFK-Brücken: Nachhaltig und zukunftsorientiert

Fuß- und Radwegbrücke Nienburg

Fuß- und Radwegbrücke NienburgGP Hoch- und Ingenieurbau GmbH - Ihr Partner für zukunftsweisende Bauvorhaben. Als innovativer Brückenbauer realisieren wir individuelle GFK-Brücken für höchste Ansprüche.

GFK-Brücken, hergestellt aus glasfaserverstärktem Kunststoff, bieten eine Vielzahl von ökologischen Vorteilen, die sie zu einer optimalen Wahl für moderne Infrastrukturprojekte machen. Im Vergleich zu herkömmlichen Materialien wie Beton oder Stahl zeigen GFK-Brücken eine deutlich geringere Umweltbelastung während ihrer gesamten Lebensdauer.

Ersatzneubau IBW46 | Zugang Vogelinsel Schloss Wittringen

Ersatzneubau IBW46 | Zugang Vogelinsel Schloss WittringenÖkologische Aspekte

- Ressourcenschonend: GFK-Brücken benötigen deutlich weniger Material als vergleichbare Stahl- oder Betonbrücken. Dies schont Ressourcen und trägt zur Reduzierung des CO2-Ausstoßes bei.

- Langlebigkeit: GFK ist extrem widerstandsfähig gegen Witterungseinflüsse, Korrosion und Chemikalien. Dadurch ist eine lange Lebensdauer der Brücken ohne aufwändige Instandhaltungsmaßnahmen gewährleistet.

- Recyclingfähigkeit: GFK ist vollständig recycelbar (annähernd 100%) und kann somit am Ende der Lebensdauer der Brücke wiederverwertet werden.

Unsere Brücken tragen somit nicht nur zur Vermeidung von Abfall bei, sondern ermöglichen auch die Wiederverwendung wertvoller Ressourcen, was im Einklang mit den Prinzipien einer Kreislaufwirtschaft steht.

Geh- und Radwegbrücke über die Erse

Geh- und Radwegbrücke über die ErseNachhaltige Vorteile

- Geringes Gewicht: Durch das geringe Eigengewicht von GFK sind die Brücken leichter zu transportieren und zu montieren. Dies minimiert den Energieverbrauch und die Umweltbelastung während der Bauphase.

- Wartungsarm: GFK-Brücken benötigen nur eine geringe Instandhaltung, was den Ressourcenverbrauch und die Kosten über die Lebensdauer der Brücke reduziert.

- Flexibilität in der Gestaltung: GFK bietet vielfältige Gestaltungsmöglichkeiten in Form und Farbe. So können wir Brücken realisieren, die sich harmonisch in die Umgebung einfügen.

Ersatzneubau Geh- und Radwegbrücke i.d. Worth ü.d. Haller

Ersatzneubau Geh- und Radwegbrücke i.d. Worth ü.d. HallerAls erfahrener Ingenieur- und Brückenbauer sind wir stolz darauf, hochwertige und nachhaltige Lösungen anzubieten, die die Anforderungen unserer Kunden erfüllen und gleichzeitig einen positiven Beitrag zur Umwelt leisten.

Wir arbeiten dabei eng mit unseren Kunden zusammen, um individuelle Lösungen zu entwickeln, die den spezifischen Anforderungen und Bedürfnissen gerecht werden.

Kontaktieren Sie uns noch heute, um mehr über unsere GFK-Brücken und deren vielfältige Anwendungsmöglichkeiten zu erfahren.

Kontakt

GP Hoch- und Ingenieurbau GmbH

GFK-Brücken: Nachhaltig und zukunftsorientiert

GFK-Brücken: Nachhaltig und zukunftsorientiert

CSC-Zertifizierung für Betonwerke mit dem Status Silber04.04.2024

Unter dem Grundgedanken des Nachhaltigen Bauens und der immer größer werdenden Nachfrage nach Green-Buildings, haben wir einige Betonwerke dahingehend nach CSC (Concrete Sustainability Council) zertifiziert und den Status Silber erhalten.

CSC-Zertifizierung für Betonwerke mit dem Status Silber

Unter dem Grundgedanken des Nachhaltigen Bauens und der immer größer werdenden Nachfrage nach Green-Buildings, haben wir einige Betonwerke dahingehend nach CSC (Concrete Sustainability Council) zertifiziert und den Status Silber erhalten.

Dabei handelt es sich um eine unabhängige Zertifizierung, die den nachhaltigen Einsatz von Beton in der Bauindustrie fördert und die Umweltfreundlichkeit von Betonprodukten bewertet.

Essenzielle Aspekte dieses Zertifikates sind das Produzieren mit geringen Umweltauswirkungen und eine verantwortungsvolle Ressourcennutzung. Es fördert die Transparenz über den Herstellungsprozess von Beton und dessen Lieferkette sowie deren Auswirkungen auf das soziale und ökologische Umfeld. Die Zertifizierung erfolgt in den Kategorien Management, Umwelt, dem sozialen Aspekt der Nachhaltigkeit sowie in den Kategorien Ökonomie und Produktkette. Die Zertifizierung umfasst sowohl das Betonunternehmen bzw. -werk als auch dessen Wertschöpfungskette.

Mit der CSC-Zertifizierung unserer Betonwerke bieten wir Anwendern, Planern und Auftraggebern nun einen besonderen Mehrwert.

Folgende Betonwerke tragen CSC-Zertifikat in Silber:

GP Betonwerke West GmbH

- Bielefeld

- Herford

- Delmenhorst

- Bremen

- Osnabrück

GP Papenburg Betonwerke Nord GmbH

- Hannover-Anderten

- Seelze-Lohnde

- Pattensen

- Braunschweig-Rüningen

- Wolfsburg-Fallersleben

GP Betonwerke Ost GmbH

- Halle

- Leipzig

- Bitterfeld

- Wernigerode

- Gerbstedt/OT Hübitz (Siersleben)

CSC-Zertifizierung für Betonwerke mit dem Status Silber

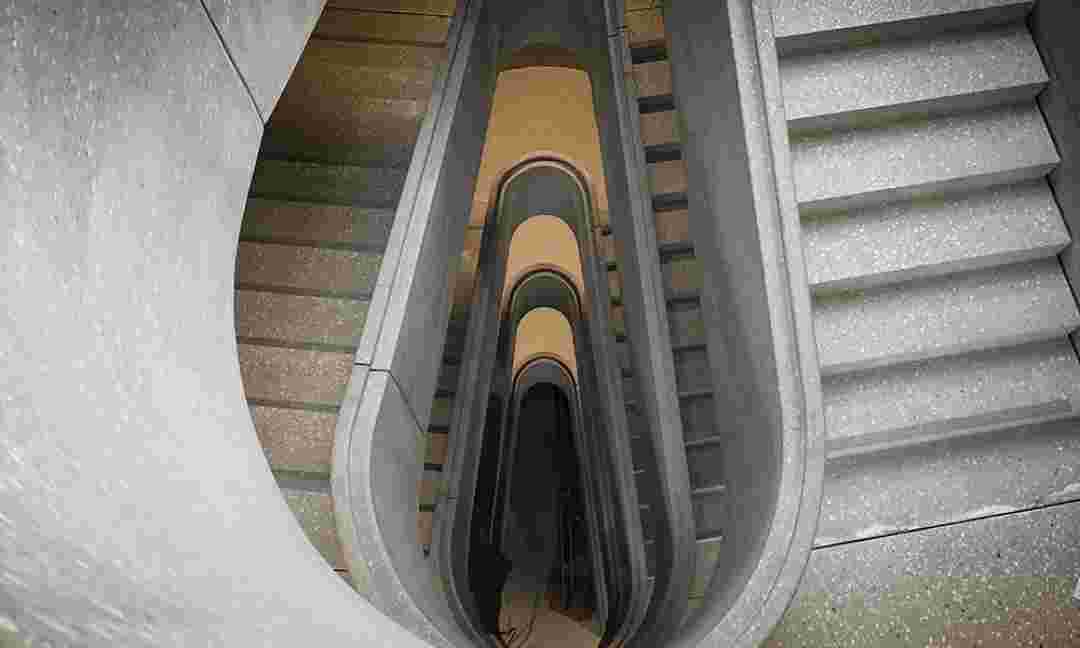

Spezialtiefbau - Optimale Lösungen auf technisch hohem Niveau29.06.2023

Die GP Spezialtiefbau GmbH ist ein pflichtbewusster und innovativer Partner, der Ihnen für die Verwirklichung Ihrer Bauvorhaben im Spezialtief mit allen Fragen und Antworten zur Seite steht.

Spezialtiefbau - Optimale Lösungen auf technisch hohem Niveau

Die GP Spezialtiefbau GmbH ist ein pflichtbewusster und innovativer Partner, der Ihnen für die Verwirklichung Ihrer Bauvorhaben mit allen Fragen und Antworten zur Seite steht. Langjährige Erfahrung und die daraus gewonnenen Kompetenzen haben uns zu einem leistungsstarken Unternehmen Deutschlands gemacht. Die Einsatzbereitschaft unserer Mitarbeiter sowie deren Fachkenntnis und technisches Know-how garantieren Ihnen optimale Lösungen auf technisch hohem Niveau.

Unser Know-how, Ihr Vorteil

Unsere Erfahrung fundiert auf vielen abgeschlossenen Bauvorhaben der verschiedensten Arten des Spezialtiefbaus. Unter anderem für die Deutsche Bahn, Autobahndirektionen in Bayern, Niedersachsen, Sachsen & Sachsen-Anhalt, sowie den Städten Leipzig und Halle (Saale).

Darüber hinaus haben Sie die Möglichkeit, auch nur Geräte mit oder ohne Personal bei uns zu mieten.

Maschinenvermietung ohne Personal

Realisieren Sie mit Ihrem Personal und unserer Technik Ihre Spezialtiefbauleistungen.

Vollständige Auftragsübernahme

Wir realisieren vollständig und in Eigenverantwortung Ihre Projekte.

Maschinenvermietung mit Personal

Wir realisieren unter Ihrer Anweisung mit unserem Personal und unserer Technik Ihre Spezialtiefbauleistungen.

Spezialtiefbau - Optimale Lösungen auf technisch hohem Niveau

Spezialtiefbau - Optimale Lösungen auf technisch hohem Niveau

Schonung von Energie- und Rohstoffquellen23.02.2023

Unsere Rohstoffvorkommen sind endlich, dessen sind wir uns bewusst. Die Bedeutung von Recycling & Verwertung ist für uns in den vergangenen Jahrzehnten enorm gewachsen. Dabei ist unser Leistungsspektrum vielfältig.

Schonung von Energie- und Rohstoffquellen

Unsere Rohstoffvorkommen sind endlich, dessen sind wir uns bewusst. Die Bedeutung von Recycling und Verwertung ist für uns in den vergangenen Jahrzehnten enorm gewachsen. Dabei ist unser Leistungsspektrum vielfältig: Die Baustoffe werden zu Sekundärrohstoffen verarbeitet und wiederverwendet. Für die Materialien, die nicht weiter recycelt werden können, bieten wir eine umweltgerechte, sichere Entsorgung auf unseren zertifizierten Deponien an. Schonung der Energie- und Rohstoffquellen und Effektivität im Bau - mit ökologischem Wirtschaften meinen wir, was wir sagen.

Schonung von Energie- und Rohstoffquellen

Schonung von Energie- und Rohstoffquellen

Maschinentechnik, die begeistert28.04.2023

In der GP Papenburg Maschinentechnik GmbH ist die gesamte Technik unserer Bauunternehmen zusammengefasst, sodass sich heute ein Team von 45 Mitarbeiterinnen und Mitarbeitern um alle technischen Belange im Bereich Vermietung, An- und Verkauf sowie den Service am Hauptsitz in Hannover kümmert.

Maschinentechnik, die begeistert

Seit 2004 wurde in der GP Papenburg Maschinentechnik GmbH die gesamte Technik unserer Bauunternehmen zusammengefasst, sodass sich heute ein Team von 45 Mitarbeiterinnen und Mitarbeitern um alle technischen Belange im Bereich Vermietung, An- und Verkauf sowie den Service am Hauptsitz in Hannover kümmert.

5.300 Geräte, darunter 600 Baumaschinen, 40 Hochbau-Krane, 400 Baustellen-Container und 4000 Kleingeräte für den Hoch- und Tiefbau werden so zentral disponiert und betreut.

Über unsere Bauhöfe in Hannover-Misburg, Schönebeck und Halle (Saale) bedienen wir außerdem unseren Hoch- und Ingenieurbau mit diversen Schalungssystemen und Hochbautechniken.

Tätigkeitsfelder

- Maschinentechnische Betreuung und Unterstützung der Bauunternehmen der GP Gruppe einschließlich der logistischen Abwicklung

- Mobiler Reparatur- und Wartungsdienst (auch direkt auf Baustellen)

- Fuhrpark-Management

- Digitale Baustelle: Intelligente Baumaschinen, Maschinensteuerung und Vermessungstechnik inklusive Nutzung von Drohnentechnologie optimieren den Baustellenprozess

Maschinentechnik, die begeistert

Maschinentechnik, die begeistert

Maschinentechnik, die begeistert

Qualität und Knowhow aus Niedersachsen13.11.2023

Die GP Papenburg Baugesellschaft mbH zählt zu einem der führenden Erd- und Straßenbauunternehmen im norddeutschen Raum und hat diverse Großbauprojekte deutschlandweit abgewickelt.

Qualität und Knowhow aus Niedersachsen

Die GP Papenburg Baugesellschaft mbH

mit Sitz in Hannover ging aus der 1978 gegründeten Papenburg Straßen- und Tiefbau GmbH & Co. KG hervor und wurde 1995 umfirmiert.

Mit rund 150 Mitarbeiterinnen und Mitarbeitern gehört sie zu den führenden Erd- und Straßenbauunternehmen im norddeutschen Raum mit Großbauprojekten deutschlandweit. Termintreu und fachkompetent wird Know-how und Erfahrung zur Optimierung multinationaler Infrastruktur eingebracht.

So ist das Unternehmen seit 2000 auch im Ausland tätig, beispielsweise mit Straßenbauprojekten im Kosovo, in Georgien, Aserbaidschan, Kasachstan und Usbekistan.

Zertifikate

Tätigkeitsfelder

- Straßenbau

- Betondeckenbau

- Erd- und Tiefbau, Kanalbau

- Bahntrassenbau

- Deponiebau

- Abbruch & Recycling

Ausgewählte Referenzen

- Flugplatz Wunstorf, Anpassung der Abstellflächen für A400M, 3. BA

- B 209, Ortsdurchfahrt Rethem, Fahrbahnerneuerung

- BAB A7, AS Soltau – AS Walsrode, RiFa Hamburg, provisorische Verbreiterung

- BAB A27, Erneuerung der PWC-Anlage Krelingen

- Wohngebiet "Buchholzer Grün", Erschließungsmaßname, ehemals Oststadtkrankenhaus

- B3 Ortumgehung Hemmingen

- B6, Klein Förste bis Hildesheim Fahrbahnerneuerung

Flugplatz Wunstorf

Flugplatz WunstorfQualität und Knowhow aus Niedersachsen

Qualität und Knowhow aus Niedersachsen

Qualität und Knowhow aus Niedersachsen

Qualität und Knowhow aus Niedersachsen

Qualität und Knowhow aus Niedersachsen

Qualität und Knowhow aus Niedersachsen

Qualität und Knowhow aus Niedersachsen

Qualität und Knowhow aus Niedersachsen

Transportbeton - der Alleskönner09.03.2023

Unsere Betonwerke sind Ihr regionaler Experte für die Produktion von hochwertigem Beton für nahezu alle Anwendungsbereiche.

Transportbeton - der Alleskönner

Unsere Betonwerke sind Ihr regionaler Experte für die Produktion von hochwertigem Beton für nahezu alle Anwendungsbereiche.

Zur Herstellung unserer Betone beziehen wir die Ausgangsstoffe größtenteils aus dem Umfeld unserer Produktionsstätten. Alle Baustoffe unterliegen strengen Qualitätskontrollen. Als Unternehmen für Transportbeton und Betonpumpen liegt der Fokus nicht nur auf der Produktion, sondern auch auf pünktlicher und fachgerechter Auslieferung. Dank unserer Regionaldisposition haben wir jederzeit alle Fahrzeuge im Blick und können Baustellen auf kurzen Wegen mit modernsten Fahrzeugen effizient beliefern.

Nicht nur auf diese Weise tragen wir zum Umweltschutz bei, sondern beispielsweise auch durch den Einsatz regional hergestellter hüttensandhaltiger Zemente, die unseren CO2-Fußabbdruck um bis zu 50% gegenüber dem deutschen Durchschnitt senken.

Transportbeton - der Alleskönner

Transportbeton - der Alleskönner

Transportbeton - der Alleskönner

Ingenieurbau im norddeutschen Raum14.03.2024

Gestützt auf kompetente Mitarbeiter unterschiedlichster Fachdisziplinen bieten wir im Ingenieurbau Komplettlösungen mit hohem Standard einschließlich Konstruktion an.

Ingenieurbau im norddeutschen Raum

GP Hoch- und Ingenieurbau GmbH

mit Hauptsitz in Hannover hat sich zu einem der führenden Bauunternehmen in der Region Hannover entwickelt. Zahlreiche Großbauprojekte wurden deutschlandweit abgewickelt. Unsere Tätigkeitsschwerpunkte liegen im sowie im Bereich Ingenieur- und Infrastrukturbau. Neben klassischem Ingenieurbau realisieren wir Industrie-, Verwaltungs-, Wohn- und Geschäftsgebäude für private, industrielle und öffentliche Auftraggeber.

Als Generalunternehmer steuern wir die gesamte Projektabwicklung und sind Ansprechpartner für unseren Kunden - von der Planung, Entwicklung und Beratung, über die Ausführung von Tief-, Roh- und Ausbauarbeiten bis zur schlüsselfertigen Übergabe - alles aus einer Hand. Zum wichtigsten Betätigungsfeld zählt die eigene und die großflächige Baumaßnahme in der .

Der Qualitätsanspruch unserer eigenen Mitarbeitenden und die enge Zusammenarbeit der verbundenen Bauunternehmen begründet unseren Erfolg als Familienunternehmen. Unser stetiges Wachstum unterstreicht dabei den nachhaltigen Erfolg unseres Handelns.

Sorgfältige Planung, innovatives Denken und gute Partnerschaft stehen im Vordergrund unserer Arbeit.

Tätigkeitsfelder

- Ingenieurbau - Brückenbau

- Ingenieurbau - Randträgersicherung

- Ingenieurbau - Industriebau

- Infrastrukturbau für Verkehrswege und Wasserstraßen

Industrie- und Anlagenbau

Industrie- und AnlagenbauKonstruktives Bauen beginnt bereits mit der richtigen Planung. Hier zählt der ganzheitliche Blick.

Planung und Ausführung, Entwurf, Konstruktion sowie die technische Umsetzung des Ingenieurbauwerks erfolgen stets in enger Zusammenarbeit mit dem Auftraggeber, wobei auf dessen spezielle Anforderungen und Schwerpunkte eingegangen wird.

Gerne stellen wir Ihnen mit passgenauen Lösungen unser technisches Know-how unter Beweis.

Brückenbau

BrückenbauNeben konventionellen Brücken bauen wir auch mit Glasfaser verstärkte Brücken als Verbundkonstruktionen. Die Brücken werden vollständig im Werk gefertigt und als komplette Brücke zum Einbauort transportiert. Sie zeichnen sich durch geringes Eigengewicht aus, was wirtschaftliche Gründungen und kleine Hebegeräte ermöglicht. Für den Einsatz in anspruchsvollem Bauumfeld sind sie von großem Vorteil.

Referenzen

- KVA, Hannover

- Eisenbahnbrücken in Hannover, Strecke 1750, Wunstorf - Lehrte

- Neubau der 2. Schleuse Zerben

Schleusenbau

SchleusenbauZertifikate

Bescheinigungen

Ingenieurbau im norddeutschen Raum

Ingenieurbau im norddeutschen Raum

Ingenieurbau im norddeutschen Raum

Ingenieurbau im norddeutschen Raum

Erfahrene Wegbereiter29.06.2023

Jedes Bauprojekt stellt für die GP Verkehrswegebau GmbH eine individuelle Herausforderung dar. Von der Planung bis zur Fertigstellung arbeiten wir mit einem Höchstmaß an Verantwortung und Leidenschaft. Termintreue ist für uns eine Selbstverständlichkeit.

Erfahrene Wegbereiter

GP Verkehrswegebau GmbH

Aus der 1990 gegründeten HALL-BAU GmbH entstand 2009 durch Umfirmierung die GP Verkehrswegebau GmbH mit Hauptsitz in Halle (Saale) und Niederlassungen in Leipzig und Grimmen.

Die 410 Mitarbeiter:innen sind im Straßen-, Tief-, Erd-, Deponie, Deich-, Kanal-, Gleis-, Ingenieur- und Wasserbau sowie Asphalteinbau tätig, wobei vorrangig Bauvorhaben in den neuen Bundesländern abgewickelt werden.

Zum Aufgabengebiet gehören neben dem Neubau und der Rekonstruktion von Straßen aller Bauklassen auch der Erdbau, sowie Bauvorhaben vom kleineren Baugrubenaushub bis hin zu Streckenbauwerken mit mehreren Millionen Kubikmetern Erdbewegungen.

Tätigkeitsfelder

- Straßenbau in Asphalt und Beton

- Erdbau

- Tiefbau

- Deponiebau

- Deichbau

- Kanalbau

- Gleisbau

- Umwelttechnik

- Wasserbau

- Ingenieurbau

- Brücken (Neubau, Sanierung und Instandsetzung)

- Tunnel

- Überführungen/Tröge

Die Niederlassung Gleisbau führt komplexe Straßenbahn-Bauprojekte sowie den Bau von Gleisanlagen und deren Instandhaltung auf regionaler und überregionaler Ebene durch.

Referenzen

- Stadtbahnprogramm Halle (Saale) - Südstadtring und Gimritzer Damm

- ZBA Güterbahnhof Halle (Saale)

- Schleusenbrücke Bernburg (Saale)

- L 63 OU Brumby

- BAB A14

- B 91 Saaleflutbrücke

- B 80 Brücke

Konsequente Investitionspolitik

Unsere konsequente Investitionspolitik gewährleistet, dass uns für alle Leistungsbereiche modernste Geräte- und Steuerungstechnik zur Verfügung stehen. Außerdem können wir aus der GP Gruppe auf einen Fuhrpark mit 250 modernen Fahrzeugen zurückgreifen.

Zertifikate | GP Verkehrswegebau GmbH

Mitglied- / Partnerschaft

Erfahrene Wegbereiter

Erfahrene Wegbereiter

Erfahrene Wegbereiter

Erfahrene Wegbereiter

Erfahrene Wegbereiter

Erfahrene Wegbereiter

Erfahrene Wegbereiter

Erfahrene Wegbereiter

Erstklassiges Material reist auch 1. Klasse24.02.2023

Die Logistik ist ein unentbehrliches Bindeglied zwischen Baustelle, Roh- und Baustoffbetrieb. Ob Transporte von Schüttgütern, Baustoffen, Bitumen und Betonwaren, in Silo-, Kran-, Planenzügen sowie bei Baumaschinen- und Schwerlasttransporten – unsere gelbe Flotte ist Ihr kompetenter Partner auf der Straße.

Erstklassiges Material reist auch 1. Klasse

Zur richtigen Zeit am richtigen Ort: Die Logistik ist ein unentbehrliches Bindeglied zwischen Baustelle, Roh- und Baustoffbetrieb. Ob Transporte von Schüttgütern, Baustoffen, Bitumen und Betonwaren, in Silo-, Kran-, Planenzügen sowie bei Baumaschinen- und Schwerlasttransporten – unsere gelbe Flotte ist Ihr kompetenter Partner auf der Straße.

Unsere Spedition ist eines unserer wichtigsten Standbeine und macht die GP Günter Papenburg AG leistungsfähig. Sowohl für unsere Kunden und Auftraggeber als auch unternehmensintern führen wir zuverlässig logistische Dienstleistungen durch. Hier setzen wir auf Effizienz: Die Engmaschigkeit unserer Werke garantiert kurze Transportwege; diese werden durch moderne Technik digital errechnet und Leerfahrten vermieden. Unser moderner Fuhrpark ist digital und innovativ ausgestattet, teilweise auch mit alternativen Antrieben.

Erstklassiges Material reist auch 1. Klasse

Unser Erfolgsrezept hat nur die besten Zutaten24.02.2023

Unsere Rohstoffe stellen eine unverzichtbare Voraussetzung für die Baustoffproduktion, den Hoch-, Ingenieur- und Verkehrswegebau dar. Ob von Nord nach Süd, von Ost nach West – für den Transport der Materialien zum Bau steht unsere umfassende Flotte bereit.

Unser Erfolgsrezept hat nur die besten Zutaten

Die besten Ideen, die perfektesten Konstruktionen, die wertvollsten Baustoffe – wer sonst kann bieten, was die Natur uns seit jeher zur Verfügung stellt? Damit ist sie nicht nur Vorlage für unsere Bauvorhaben, sondern zugleich deren Grundlage. Rohstoffe sind unverzichtbar für die Baustoffproduktion, den Hoch-, Ingenieur- und Verkehrswegebau. Ob von Nord nach Süd, von Ost nach West – für den Transport der Materialien zum Bau steht unsere umfassende Flotte bereit. Wir achten auf umweltschonende, effiziente Vorgehensweisen, denn uns ist nicht egal, wie die Welt von morgen aussieht.

Silotransporter

Silotransporter Rohstoffwerk Negenborn

Rohstoffwerk NegenbornUnser Erfolgsrezept hat nur die besten Zutaten

Unser Erfolgsrezept hat nur die besten Zutaten

Unser Erfolgsrezept hat nur die besten Zutaten

Unser Erfolgsrezept hat nur die besten Zutaten

Unser Erfolgsrezept hat nur die besten Zutaten

Unser Erfolgsrezept hat nur die besten Zutaten

Unser Erfolgsrezept hat nur die besten Zutaten

Wasserstadt Limmer Projekt13.07.2023

Bei der Umsetzung eines unserer bisher größten Projekte sind wir ganz in unserem Element: Das Entstehen der Wasserstadt Limmer zeigt das perfekte Zusammenspiel aller Sparten der GP Gruppe. Auf der Halbinsel im Nordwesten Hannovers entsteht ein neuer, einzigartiger Stadtteil.

Wasserstadt Limmer Projekt

Vielfalt an Wohnformen im neuen Quartier

Bei der Umsetzung eines unserer bisher größten Projekte sind wir ganz in unserem Element: Das Entstehen der zeigt das perfekte Zusammenspiel aller Sparten der GP Gruppe. Dabei arbeiten wir eng mit unseren Partnern, der Stadt Hannover und den Bürgerinnen und Bürgern zusammen.

Vielfältig, urban und naturverbunden

Das sind unsere Ansprüche an das neue Stadtviertel auf einer Halbinsel zwischen Leine-Auen und historischen Kanälen. Aus dem Gelände des ehemaligen Continental-Werks wird ein außergewöhnlicher Lebensraum: Abwechslungsreiche Wohnkonzepte werden mit großzügigen Grünflächen und Parkanlagen sowie Gewerbeeinheiten für Dienstleistungen und Einzelhandel ergänzt. Unsere Vision sind urbane Lebendigkeit, zeitgemäße Vielfalt und kurze Wege.

Nachhaltigkeit und Synergien

Das Quartier wurde von der Deutschen Gesellschaft für Nachhaltiges Bauen (DGNB) mit einem Vorzertifikat in Gold ausgezeichnet. Das Gütesiegel steht für die hohe Qualität des Bauvorhabens in ökonomischer, ökologischer, soziokultureller und nicht zuletzt funktionaler Hinsicht.

Gold-Status

Gold-StatusKey-Facts, die Wasserstadt im Schnelldurchlauf oder weitere Details zu den Bauabschnitten finden Sie auf

Wasserstadt Limmer Projekt

Wasserstadt Limmer Projekt

Wasserstadt Limmer Projekt

Papenburg

GP Günter Papenburg AG

Anderter Straße 99c

DE-30559 Hannover

Standorte Negenborn, Krähenwinkel, Steinwedel

Standorte Oker, Harvesse, Ringelheim

GP Günter Papenburg AG

GP Günter Papenburg AG

GP Günter Papenburg AG

GP Günter Papenburg AG

GP Günter Papenburg AG

FOLGEN SIE UNS

Social Follow Us

WERDE TEIL

UNSERES TEAMS

Ausbildung zum Verfahrensmechaniker in der Steine- und Erdenindustrie; FR vorgefertigte Betonerzeugnisse (m/w/d)

West

Ausbildung zum Verfahrensmechaniker in der Steine- und Erdenindustrie; FR Transportbeton (m/w/d)

Mitteldeutschland

Bewerberportal

Archiv

Referenzen

Archiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

refarchiv

Neuigkeiten-Archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

archiv

Ostern voller Freude dank unserer Mitarbeiter!28.03.2024

Ostern strahlte voller Freude dank der bemerkenswerten Beteiligung unserer Mitarbeiter! Wie schon in den vergangenen Jahren haben unsere Mitarbeiter an einer bezaubernden Aktion teilgenommen und Geschenke für benachteiligte Kinder gespendet und liebevoll verpackt.

Ostern voller Freude dank unserer Mitarbeiter!

Ostern strahlte voller Freude dank der bemerkenswerten Beteiligung unserer Mitarbeiter! Wie schon in den vergangenen Jahren haben unsere Mitarbeiter an einer bezaubernden Aktion teilgenommen und Geschenke für benachteiligte Kinder gespendet und liebevoll verpackt.

Insgesamt wurden 166 Geschenke wie Spielzeug, Bücher oder Kuscheltiere gesammelt und an 3 soziale Einrichtungen der Region übergeben. Darunter waren die Mattisburg der Caritas Halle, das Kinderheim „Clara Zetkin“ e. V. und die "Schnitte" des CVJM Halle e. V.. Mit großer Hingabe haben unsere Mitarbeiter diese Geschenke verpackt, um den Kindern ein unvergessliches Osterfest zu bereiten.

Die Initiative wurde von der GP Gruppe ins Leben gerufen, um Kinder in unserer Region zu unterstützen und ihnen ein schönes Osterfest zu ermöglichen. Die Geschenke wurden vor den Osterfeiertagen überreicht und die Aktion erwies sich als großer Erfolg, der zahlreiche Kinder glücklich machte.

Ein herzliches DANKESCHÖN! 💛 Wir möchten uns bei allen Mitarbeitern, die sich an dieser Aktion beteiligt haben, von ganzem Herzen bedanken. Ihr seid einfach großartig! Diese Aktion zeigt deutlich, dass Zusammenhalt und soziales Engagement bei der GP Gruppe einen hohen Stellenwert haben. #WirSindGP

Mattisburg | Caritas Halle (Saale)

Mattisburg | Caritas Halle (Saale) von Kinder der Mattisburg | Caritas Halle (Saale)

von Kinder der Mattisburg | Caritas Halle (Saale) Kinderheim Clara Zetkin e.V.

Kinderheim Clara Zetkin e.V. "Schnitte" CVJM Halle e.V.

"Schnitte" CVJM Halle e.V.Ostern voller Freude dank unserer Mitarbeiter!

Berufsorientierung auf Messen13.03.2024

Besuchen Sie uns auf einer der zahlreichen BO- und Jobmessen und werden auch Sie ein Teil der GP Gruppe.

Berufsorientierung auf Messen

Die ist eine etablierte Fachmesse für Ausbildung und Studium in verschiedenen Städten bundesweit. Sie vermittelt qualifizierte Kontakte zwischen jungen Menschen und Ausstellern aus der Wirtschaft und dem weiterführenden Bildungsbereich. Auf der Messe steht der persönliche Kontakt zwischen Schüler:innen und Ausstellern im Vordergrund. In einer intensiven Vorbereitungsphase besucht die IfT - Institut für Talententwicklung GmbH die Schulen der Region und vergibt genaue Gesprächstermine zwischen den Ausstellern und den Schüler:innen. Die Aussteller kennen bereits dann schon die Interessen und Berufswünsche der Schüler:innen und können sich somit optimal auf die Gespräche vorbereiten.

Die GP Gruppe wertet während des Gesprächstermins mit dem Jugendlichen die Neigungen, Lieblingsfächer und verschiedene Kriterien (z. B. Pünktlichkeit zu dem Termin etc.) mittels eines eigenen Fragebogens aus, um so bessere Ergebnisse in der Bewerberauswahl erzielen zu können.

Termin 2024

Wo/Wann

07.+08.05.2024 | 8:30 - 15 Uhr | Globana Trade Center Leipzig/Halle

06.+07.06.2024 | 8:30 - 15 Uhr | Hannover Congress Centrum

Auf der Mitmach-Messe im Gebäude der Mediengruppe Mitteldeutsche Zeitung können Sie mehr als 40 regionale Aussteller und ihre Berufe über praktische Aktivitäten kennenlernen. Darunter auch die GP Gruppe mit unserem GP Job-Parcours und der GP-Physikeinheit zum Experimentieren im Außenbereich. Unsere Ansprechpartner:innen stehen gerne für Fragen und Informationen rund um den Berufseinstieg zur Verfügung.

Termin 2024

Wann 14.09.2024 | 10 - 16 Uhr

Wo Mediengruppe Mitteldeutsche Zeitung,

Delitzscher Str. 65, 06112 Halle

Eine weitere Messe, auf der die GP Gruppe vertreten ist, ist die im Ständehaus Merseburg. Mit weiteren über 40 Ausstellern klären wir gern alle Fragen rund um die Themen Ausbildung, Studium und Berufseinstieg.

Termin 2024

Wann 21.09.2024

Wo Ständehaus Merseburg

Oberaltenburg 2, 06217 Merseburg

Die GP Gruppe ist gemeinsam mit dem Überbetrieblichen Ausbildungszentrum Holleben Austeller aus der Messe in Halle (Saale). In den Veranstaltungshallen des Messegeländes informieren wir an zwei Messetagen die Besucher:innen über unsere Ausbildungs- und Studienmöglichkeiten und stehen den vielen interessanten Fragen, rund um die GP Gruppe Rede und Antwort. Die Ausstellungsbereiche der werden durch zielgruppenorientierte Referate, kompetente Fachvorträge sowie themenspezifische Workshops vertieft.

Termin 2025

Wann 21.+22.02.2025

Wo HALLE MESSE | Halle (Saale)

Berufsorientierung auf Messen

100 neue Sozialwohnungen in Leipzig12.03.2024

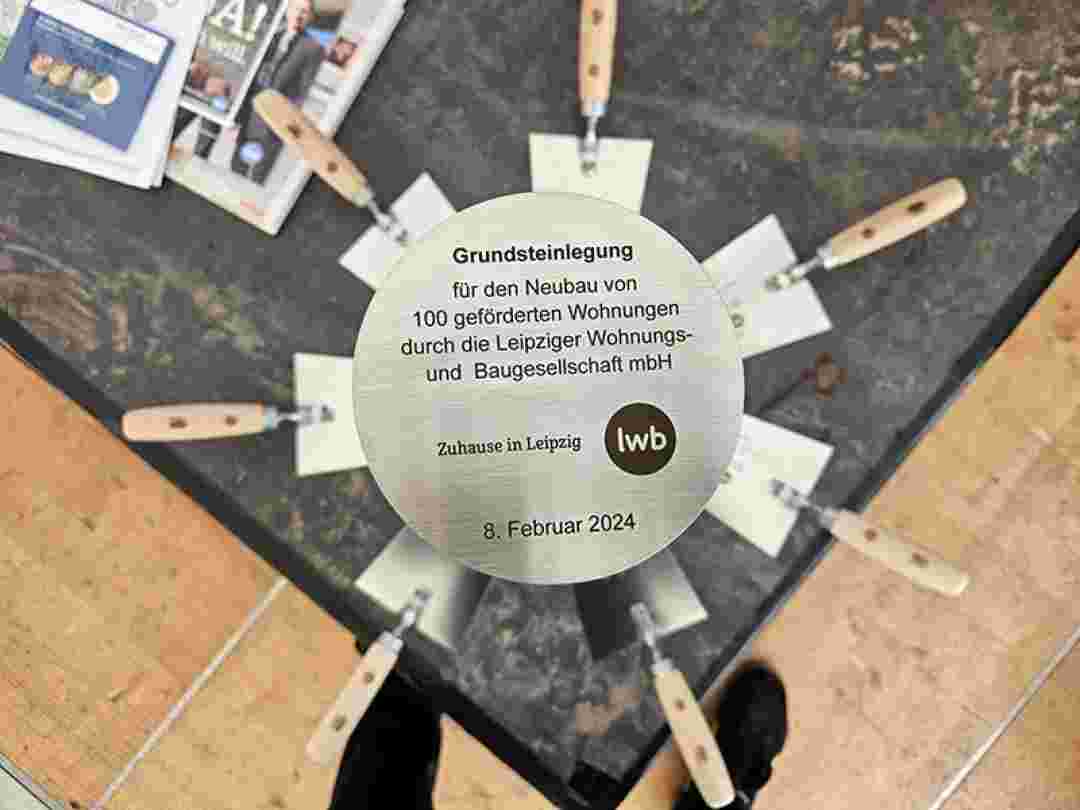

In Leipzig-Mockau entsteht ein neues Wohnquartier mit 100 geförderten Wohnungen. Die GP Papenburg Hochbau GmbH ist als Generalunternehmer für den Bau des fünf- bis siebengeschossigen Gebäudes in der Samuel-Lampel-Straße verantwortlich. Am 08. Februar 2024 fand die feierliche Grundsteinlegung statt.

100 neue Sozialwohnungen in Leipzig

Gemeinsam mit der LWB realisieren wir ein nachhaltiges Wohnquartier

Gemeinsam mit der der Leipziger Wohnungs- und Baugesellschaft mbH (LWB) realisiert die GP Papenburg Hochbau GmbH bereits das fünfte Projekt in Leipzig. Die feierliche Grundsteinlegung am 8. Februar 2024 markierte einen wichtigen Meilenstein für das Projekt in der Samuel-Lampel-Straße. Wir freuen uns, dass sowohl lokale Vertreter wie der Leipziger Baubürgermeister Thomas Dienberg und Staatssekretärin Barbara Meyer als auch unsere Niederlassungsleiter Jörg Streiber spannende Einblicke in den Bauprozess und die nachhaltigen Lösungen des Neubaus gaben.

Wir freuen uns sehr, mit dem Neubauprojekt in der Samuel-Lampel-Straße weitere 8.500 Quadratmeter geförderten, modernen und ökologisch nachhaltigen Wohnraum zur Verfügung stellen zu können. Etwa 4.200 Kubikmeter Beton und 550 Fenster werden im Objekt verbaut. Und noch eine spannende Zahl: Das benötigte Malervlies deckt etwa viereinhalb Fußballfelder ab.

Nachhaltigkeit und soziales Engagement

In dem Leipziger Stadtteil Mockau entstehen 100 neue Sozialwohnungen. Die Zwei- bis Sechs-Raum-Wohnungen bieten Platz für Familien und Singles. Alle Wohnungen verfügen über einen Balkon, eine Loggia oder einen Mietergarten. 19 Wohnungen werden barrierefrei gestaltet.

Das Projekt zeichnet sich durch seine nachhaltige Bauweise aus und wird mit begrünten Fassaden und Dächern, Photovoltaikanlagen sowie Fahrradstellplätzen und Ladestationen für E-Bikes ausgestattet sein. Ein durchdachtes Freianlagenkonzept bietet Raum für Hochbeete, Mietergärten sowie Spiel- und Aufenthaltsorte.

Wir bei der GP Papenburg Hochbau GmbH sind stolz darauf, Teil dieses zukunftsweisenden Projekts zu sein und einen Beitrag zur Entwicklung nachhaltiger Wohnkonzepte in Leipzig zu leisten.

Visualisierung | Bietergemeinschaft W&V Architekten - mbpk Architekten

Visualisierung | Bietergemeinschaft W&V Architekten - mbpk Architekten100 neue Sozialwohnungen in Leipzig

100 neue Sozialwohnungen in Leipzig

Das Jahr

2023

im Rückblick

2023

Auch 2024: Gemeinsam wachsen, innovativ gestalten!

Hier einige Bilder aus der Luft, die zeigen, was WIR 2023 GEMEINSAM geschaffen haben.

2023

Als "Beste Ausbilder 2023" ausgezeichnet14.03.2024

Die GP Günter Papenburg AG wurde mit dem Handelsblatt-Siegel "Beste Ausbilder 2023" ausgezeichnet. Die Auszeichnung würdigt die hervorragende Ausbildung von Nachwuchskräften in unserer GP Gruppe. Sie bestätigt das Engagement des Unternehmens für eine hochwertige Ausbildung von Nachwuchskräften.

Als "Beste Ausbilder 2023" ausgezeichnet

Auszeichnung für hervorragende Ausbildung

Die GP Günter Papenburg AG wurde mit dem Handelsblatt-Siegel "Beste Ausbilder 2023" ausgezeichnet. Die Auszeichnung würdigt die hervorragende Ausbildung von Nachwuchskräften in unserer GP Gruppe.

Wir bieten eine breite Palette an im Bauwesen an. Wir legen großen Wert auf eine praxisnahe Ausbildung, die den Auszubildenden die nötigen Kenntnisse und Fähigkeiten für einen erfolgreichen Start ins Berufsleben vermittelt.

Die Ausbildung bei der GP Günter Papenburg AG ist geprägt von einer familiären Atmosphäre und einem starken Teamgeist. Die Auszubildenden werden von erfahrenen Ausbildern betreut und erhalten die Möglichkeit, sich aktiv in die Unternehmensarbeit einzubringen.

Ausbildungsqualität auf höchstem Niveau

Die Auszeichnung des Handelsblatts ist ein Beleg für die hohe Qualität der Ausbildung bei der GP Günter Papenburg AG. Das Unternehmen erfüllt alle Kriterien, die für eine erfolgreiche Ausbildung von Nachwuchskräften erforderlich sind.

Dazu gehören unter anderem:

- Eine klare Ausbildungskonzeption

- Qualifizierte Ausbilder

- Praxisnahe Ausbildung

- Förderung der Auszubildenden

Die GP Günter Papenburg AG ist sich der Bedeutung von Nachwuchskräften für die Zukunft des Unternehmens bewusst. Deshalb investiert das Unternehmen in eine umfassende Ausbildungsoffensive. Ziel ist es, noch mehr junge Menschen für eine Ausbildung im Bauwesen zu begeistern.

Fazit

Die Auszeichnung des Handelsblatts ist eine große Ehre für die GP Günter Papenburg AG. Sie bestätigt das Engagement des Unternehmens für eine hochwertige Ausbildung von Nachwuchskräften.

Das Marktforschungsinstitut SWI Human Resources (SWI HR) hat für das Handelsblatt die Ausbildungsbedingungen von knapp 2.400 Unternehmen analysiert und in einem zusammengefasst. Die Unternehmen wurden unter anderem danach bewertet, wie viele ihrer Lehrlinge einen ausgezeichneten Abschluss machen, wie die Unternehmen ihre Azubis fördern und wie die Ausbildung vergütet wird.

Als "Beste Ausbilder 2023" ausgezeichnet

GP Arbeitgeber der Zukunft 202310.01.2024

Erfreuliche Auszeichnung für die GP Günter Papenburg AG. Wir sind "Arbeitgeber der Zukunft" 2023 und wurden als GP Gruppe vom Deutschen Innovationsinstitut für Nachhaltigkeit und Digitalisierung (DIND) in Zusammenarbeit mit der Deutschen Unternehmer Plattform (DUP) ausgezeichnet.

GP Arbeitgeber der Zukunft 2023

Unternehmen in Deutschland sehen sich derzeit mit einer Vielzahl an Herausforderungen konfrontiert. Neben Krieg, Inflation und Klimakrise müssen sich Betriebe zunehmend mit der demografischen Entwicklung und dem damit einhergehenden, zuspitzenden Engpass an Fachkräften auseinandersetzen. Ein entscheidender Wettbewerbsfaktor ist daher die Positionierung als attraktiver Arbeitgeber im „War for Talents“.

Dies ist der GP Günter Papenburg AG gelungen und wurde vom Deutschen Innovationsinstitut für Nachhaltigkeit und Digitalisierung (DIND) in Zusammenarbeit mit der DUP UNTERNEHMER als "Arbeitgeber der Zukunft" 2023 ausgezeichnet.

Ausschlaggebend für diese Auszeichnung waren die Themenbereiche Digitalisierung und Nachhaltigkeit. Weitere Bewertungskriterien für das Siegel "Arbeitgeber der Zukunft" sind:

- Moderne Führung

- Innovationskraft

- Stand der digitalen Transformation

- Mitarbeiterfreundlichkeit

- Strategien fürs Recruiting

Wir sind sehr froh, dass wir den mehrstufigen Prüfprozess und die eingehende Prüfung gemeistert haben. In Zeiten des Fachkräftemangels ist es umso wichtiger, sich als zukunftsfähiges, innovatives Unternehmen zu positionieren, das sich permanent weiterentwickelt, um erfolgreich am Markt bestehen zu können. Dabei ist die Etablierung einer modernen Unternehmenskultur ein fortwährender Prozess, zu dem viele neue Ideen gehören und bei dem die Mitarbeitenden mitgenommen werden müssen. Daher geht ein großer Dank an alle Beteiligten für die Nominierung und allen Mitarbeitern und Mitarbeiterinnen der GP Gruppe!

GP Arbeitgeber der Zukunft 2023

Regional, nachhaltig und beständig09.01.2024

Zur Herstellung unserer Betone beziehen wir die Ausgangsstoffe, wie Zement, Kies und Sand, zum größten Teil aus dem Umfeld unserer Transportbetonwerke. Durch unsere Regionaldisposition haben wir alle Fahrzeuge im Blick und können Ihre Baustellen auf kurzen Wegen mit modernsten Fahrzeugen effizient beliefern. Aber unser Beton kann noch mehr.

Regional, nachhaltig und beständig

Wir setzen auf Nachhaltigkeit

Der CO2-Footprint von Beton wird zu rund 80 % durch den Zement beeinflusst. Wir verwenden für die Herstellung unserer Betone regional hergestellte, hüttensandhaltige Zemente mit einem deutlich reduzierten CO2-Footprint. Allerdings verringern diese Zemente nicht nur die CO2-Emissionen, sondern schonen auch unsere natürlichen Ressourcen.

Gegenüber einem generischen deutschen Durchschnittszement mit 587 kg CO2-eq (Quelle: EPD Verein Deutscher Zementwerke) haben die von uns standardmäßig verwendetet Hochofenzemente CEM III/A bereits einen um 36% reduzierten CO2-Footprint. Nochmals deutlich günstiger ist die Ökobilanz der CEM III/B Zemente, die eine Reduzierung von über 50 % aufweisen.

Klimafreundliche und dauerhafte Betone

Sie erhalten klimafreundliche Betone mit CEM III/A- und CEM III/B-Zementen in den Festigkeitsklassen C12/15, C16/20, C20/25, C25/30 und C30/37 und je nach Anwendung in verschiedenen Körnungen für Innenbauteile im Hochbau, für bewehrte Außenbauteile oder für Gründungsbauteile. Alle Betone entsprechen den Normen der DIN EN 206 und DIN 1045-2.

Zur Erreichung höherer Anfangsfestigkeiten ist der Einsatz von Erhärtungsbeschleuniger möglich. Die Dosierung wird den jeweiligen Anforderungen angepasst.

R-Beton oder Recyclingbeton

Dieser kann bei einigen Anwendungen gleichwertig eingesetzt werden und verbessert die CO2 Bilanz nochmals. Im Bedarfsfall erstellen wir eine geeignete Betonsorte anhand der geforderten Eigenschaften. Recyclingbetone sind noch nicht an allen Standorten verfügbar.

Regional, nachhaltig und beständig

Regional, nachhaltig und beständig

Durchgängige Telematiknachrüstung durch die Maschinentechnik02.02.2024

Die GP Papenburg Maschinentechnik GmbH rüstet alle Baumaschinen, welche nicht mit einer Telematikeinheit ausgestattet sind, mit einem Trackingsystem nach.

Durchgängige Telematiknachrüstung durch die Maschinentechnik

Die GP Papenburg Maschinentechnik GmbH rüstet alle Baumaschinen, welche nicht mit einer Telematikeinheit ausgestattet sind, mit einem Trackingsystem nach. Somit soll im Jahr 2024 eine vollständige Telematikabdeckung der Baumaschinen in der Papenburg Gruppe erreicht werden.

Zukünftig werden auch von älteren Geräten Standort, Betriebsstunden sowie Last- und Leerlaufzeiten aufgenommen. Dies erhöht die Transparenz über den Maschinenpark und unterstützt unsere Mitarbeiter in der Disposition und Werkstatt.

Durchgängige Telematiknachrüstung durch die Maschinentechnik

Durchgängige Telematiknachrüstung durch die Maschinentechnik

Digitale Berufsorientierung - Der GP Zukunfts-Chat10.04.2024

Berufsorientierung einmal anders! Sei dabei - Jeden 2. Dienstag im Monat dreht sich bei uns alles um die Berufsorientierung und das DIGITAL! MACH MIT und stell deine Fragen in unserer Onlineveranstaltung zu Ausbildung, Studium und Praktika bei der GP Gruppe.

Digitale Berufsorientierung - Der GP Zukunfts-Chat

Berufsorientierung einmal anders!

Seit Oktober 2023 starten wir einmal im Monat mit unserer digitalen Berufsorientierung – dem GP Zukunfts-Chat! Sei dabei und klick dich rein!

Ganz gleich, ob Schülerinnen und Schüler, Eltern oder Großeltern, Lehrerinnen und Lehrer, wir stehen dir jeden 2. Dienstag im Monat LIVE zur Verfügung, um alle deine Fragen zu Ausbildungsberufen, dualen Studiengängen, dem Bewerbungsverfahren sowie dem Ablauf einer Ausbildung oder eines dualen Studiums zu beantworten.

Darüber hinaus erhältst du wertvolle Tipps zur Berufsfindung und einen Einblick in die vielfältigen Möglichkeiten, die die GP Gruppe während und nach einer Ausbildung oder eines dualen Studiums bietet.

Wir freuen uns auf dich!

Kommende Termine

Jeden 2. Dienstag im Monat von 17 - 18 Uhr

- 09. April 2024

So nimmst du DIGITAL teil

Die digitale Berufsorientierung findet mit der Software "Microsoft Teams" statt. Diese kann auf PCs, Tablets und auch Smartphones verwendet werden. Eine Installation ist nicht zwingend notwendig, das Programm läuft auch auf allen gängigen Internet-Browsern.

Link zum Meeting:

Oder scanne einfach den QR-Code ..

Datenschutzhinweis für Teilnehmende

Für die Nutzung von MS Teams ist die Verarbeitung deiner IP-Adresse in den USA erforderlich. Die Verarbeitung erfolgt im Rahmen der Auftragsverarbeitung gem. Art. 28 DSGVO und auf Grundlage des Angemessenheitsbeschlusses EU-U.S. Data Privacy Framework gemäß Art. 45 DSGVO. Alle Informationen zum Datenschutz findest du auf

Digitale Berufsorientierung - Der GP Zukunfts-Chat

Vertragsunterzeichnung - Neubau eines Premier Inn Hotels in Halle (Saale)03.04.2024

Auf der Münchener Immobilienmesse EXPO REAL unterzeichneten heute Vertreter von Premier Inn und der Saalesparkasse als Investorin den entsprechenden Hotelmietvertrag. Die GP Papenburg Hochbau GmbH als Tochtergesellschaft der GP Günter Papenburg AG, fungiert als Projektentwicklerin und Generalübernehmerin für das Vorhaben.

Vertragsunterzeichnung - Neubau eines Premier Inn Hotels in Halle (Saale)

Mit dem Neubau eines Hotels in Halle (Saale) setzt die Hotelkette , Tochter des britischen Hospitality-Konzerns Whitbread, ihre starke Expansion in Deutschland fort. Auf der Münchener unterzeichneten heute Vertreter von Premier Inn und der Saalesparkasse als Investorin den entsprechenden Hotelmietvertrag. Die als Tochtergesellschaft der GP Günter Papenburg AG, fungiert als Projektentwicklerin und Generalübernehmerin für das Vorhaben.

„Wir sind überglücklich über diesen Deal“, so Stanislav Reising, Acquisition Manager bei Premier Inn Deutschland.

„Halle an der Saale passt perfekt zu uns, da die Stadt auf vorbildliche Weise Tradition und Fortschritt vereint. Mit dem geplanten Zukunftszentrum für Deutsche Einheit und Europäische Transformation wird die Metropolregion Mitteldeutschland langfristig weiter an Bedeutung gewinnen.“

Auch Dr. Jürgen Fox, Vorstandsvorsitzender der Saalesparkasse, ist sich sicher:

„Eine Investition wie diese steht und fällt mit den richtigen Partnern. Mit der GP Papenburg Hochbau GmbH als GÜ haben wir mehrfach nur beste Erfahrungen gemacht und mit der Premier Inn Deutschland einen langfristigen Nutzer mit ambitionierten Zielen gebunden. Wir freuen uns auf die Zusammenarbeit.“

von links: Dr. Robert Franke, IMG Sachsen-Anhalt | Klaus Papenburg, GP Günter Papenburg AG | Sven Schulze, Wirtschaftsminister Sachsen-Anhalt | Ebert Geier, Bürgermeister Halle (Saale) | Stanislav Reising und Chris-Norman Sauer, Premier Inn | Foto: Tom Schulze

von links: Dr. Robert Franke, IMG Sachsen-Anhalt | Klaus Papenburg, GP Günter Papenburg AG | Sven Schulze, Wirtschaftsminister Sachsen-Anhalt | Ebert Geier, Bürgermeister Halle (Saale) | Stanislav Reising und Chris-Norman Sauer, Premier Inn | Foto: Tom SchulzePremier Inn sichert sich Toplage in Halle an der Saale

Das Premier Inn Halle Am Opernplatz, wie das Hotel heißen wird, entsteht auf einem derzeit noch unbebauten Grundstück direkt hinter dem historischen Opernhaus, nur wenige Gehminuten von der halleschen Fußgängerzone entfernt. Das Haus mit einer Bruttogrundfläche von ca. 4.000 m2 wird über 113 Zimmer verfügen, die sich auf fünf Etagen verteilen, darunter mehrere geräumige Premier Plus Rooms. Die eigene Tiefgarage, welche sich über zwei Geschosse erstreckt, umfasst neben teilweise mit Ladestationen ausgestatteten Pkw-Parkplätzen auch Fahrradstellplätze sowie Lager- und Technikflächen.

Visualisierung Premier Inn - Ansicht Kapellengasse Ecke - Halle (Saale)

Visualisierung Premier Inn - Ansicht Kapellengasse Ecke - Halle (Saale) Visualisierung Premier Inn - Ansicht Unterberg/Kapellengasse - Halle (Saale)

Visualisierung Premier Inn - Ansicht Unterberg/Kapellengasse - Halle (Saale)Die GP Gruppe konnte bereits mehrere Hotelprojekte in der Händelstadt erfolgreich realisieren. Daher ist die Freude über den Vertragsabschluss auch hier groß. Klaus Papenburg, Vorstand der GP Günter Papenburg AG, meint:

„Spätestens Mitte nächsten Jahres wollen wir mit dem Bau des Projektes beginnen, so dass in 2026 die ersten Gäste Zimmer, Service und Atmosphäre des neuen Hotels genießen können. Wir gehen fest davon aus, dass dieser erstmaligen Zusammenarbeit mit Premier Inn weitere Projekte folgen werden.“

Vertragsunterzeichnung - Neubau eines Premier Inn Hotels in Halle (Saale)

Vertragsunterzeichnung - Neubau eines Premier Inn Hotels in Halle (Saale)

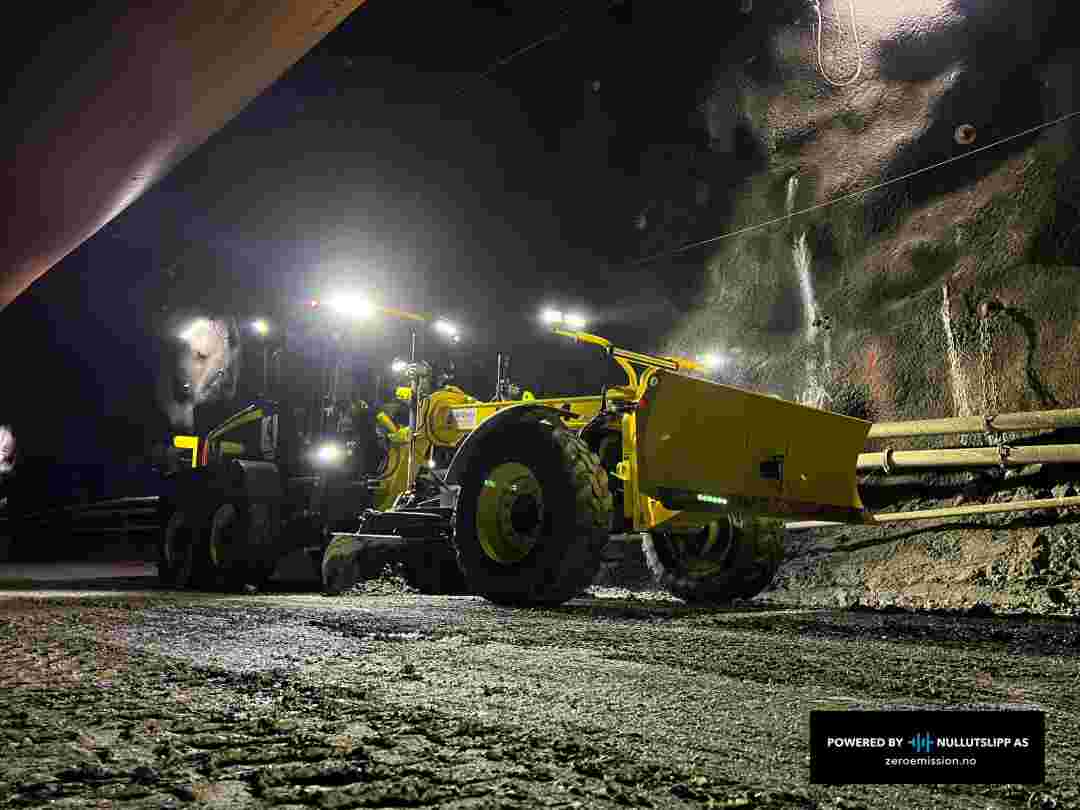

Ein Gigant mit E-Antrieb14.03.2024

Stolz kann die GP Papenburg Maschinenbau GmbH - HBM-NOBAS sein!! Der WELTWEIT erste umgebaute Motorgrader mit einem Gewicht von satten 15,5 Tonnen, heißt BG 120 TA-E und wird in Nordhausen gebaut.

Ein Gigant mit E-Antrieb

Stolz kann die GP Papenburg Maschinenbau GmbH - HBM-NOBAS sein!! Der WELTWEIT erste umgebaute Motorgrader mit einem Gewicht von satten 15,5 Tonnen, heißt BG 120 TA-E und wird in Nordhausen gebaut.

Der Umbau durch die zum E-Antrieb war (und ist) ein Gemeinschaftsprojekt.

Während der Tunnelarbeiten am „Projekt Neue Wasserversorgung für Maridalsvannet in der Gemeinde Oslo“ ist der Straßengrader nun seit fast sechs Monaten täglich im Einsatz.

Die Bauzeit der Maschine dauerte etwa 6 Monate und der Akku sorgt für einen Dauerbetrieb von 8 bis 10 Stunden.

Der BG 120 TA-E im Einsatz in Oslo | Bildquelle: Nullutslipp AS

Der BG 120 TA-E im Einsatz in Oslo | Bildquelle: Nullutslipp AS Der BG 120 TA-E im Einsatz in Oslo | Bildquelle: Nullutslipp AS

Der BG 120 TA-E im Einsatz in Oslo | Bildquelle: Nullutslipp AS

Datenblatt BG 120 TA-E

Ein Gigant mit E-Antrieb

Ein Gigant mit E-Antrieb

Mehr als Bau: GP setzt auf Mitarbeitergesundheit und Teamspirit05.10.2023

Die GP Gruppe zeichnet sich nicht nur durch ihre Erfolge im Bau aus, sondern auch durch ihr Engagement für Gesundheitsförderung, Gesundheitsmanagement und Teambuilding.

Mehr als Bau: GP setzt auf Mitarbeitergesundheit und Teamspirit

Die GP Gruppe zeichnet sich nicht nur durch ihre Erfolge im Bau aus, sondern auch durch ihr Engagement für Gesundheitsförderung, Gesundheitsmanagement und Teambuilding.

Gesundheit und Wohlbefinden der Mitarbeiter stehen hier im Mittelpunkt. Das Unternehmen bietet regelmäßige Gesundheitschecks, Seminare, Aktionstage sowie eine "Aktive Bewegungspause". Dabei arbeitet die GP Gruppe eng mit der IKK gesund plus zusammen.

einige Aktionstage und Seminare

- "Vitamine am Arbeitsplatz" - frisches Obst & Gemüse

- Mobilitätstombola

- Sonnenschutz

- Zeckenschutz

- Tag der Rückengesundheit

- "Sommer, Sonne, Schweißperlen“ - Trinken Sie sich fit

- Grippeschutz

- Gesundheitstag für Kraftfahrer

- Suchtprävention

- "Stressfrei durch die Prüfungszeit" für Azubis

Sport verbindet und stärkt

Das Teambuilding wird durch diverse Sportveranstaltungen gefördert, an denen die Mitarbeiter teilnehmen können. Diese Aktivitäten stärken nicht nur den Teamgeist, sondern auch die Gesundheit und das Wohlbefinden der Belegschaft.

GP Radtour | Mai 2023

GP Radtour | Mai 2023sportliche Veranstaltungen

- Aktive Bewegungspause

- Sportkurs "Rückenhalt"

- Firmenläufe, Lauf-Events, Triathlon

- GP Drachenboot-Cup

- GP Radtour

- GP Harzwanderung (Benefizwanderung)

- Volleyball-Turniere

- Mobilitätstombola

GP Harzwanderung | Oktober 2019

GP Harzwanderung | Oktober 2019Der Erfolg hängt an den Mitarbeitenden

Insgesamt zeigt die GP Gruppe, dass sie nicht nur ein erfolgreiches Bauunternehmen ist, sondern auch großen Wert auf das Wohlbefinden und die Zusammenarbeit ihrer Mitarbeitenden legt.

Dies ist ein wichtiger Faktor für den langfristigen Erfolg des Unternehmens.

.. und am Ende sitzen wir alle im gleichen Boot ;o)

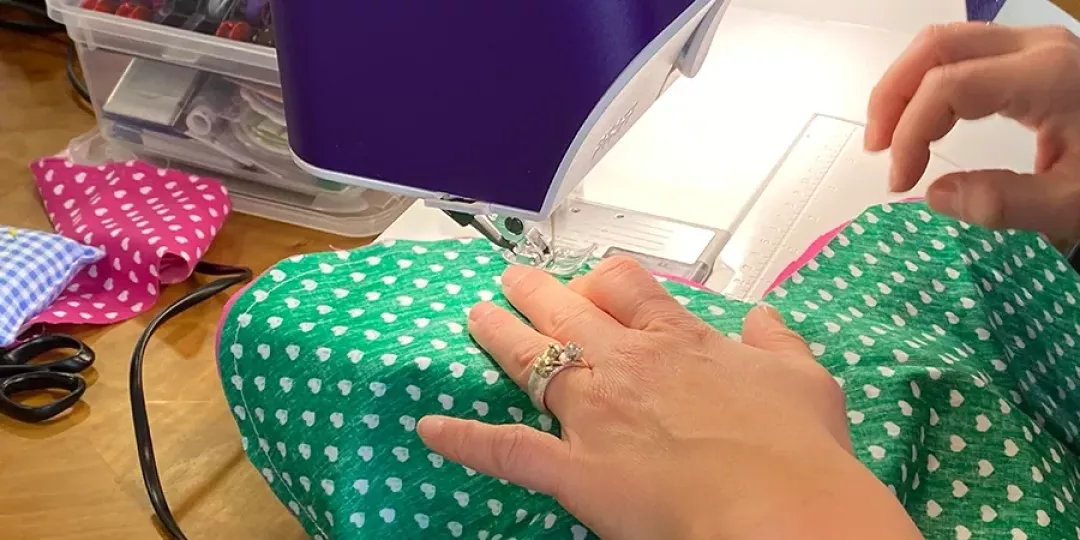

Mit Nadel und Faden, schenken wir Freude und Hoffnung

Die Herzkissen-Aktion ist seit Jahren ein fester Bestandteil in der GP Gruppe. Hier nähen Mitarbeitende Herzkissen für krebskranke Frauen.

Auch hier ist Teamwork gefragt – zuschneiden, nähen, befüllen und verpacken. Diese Mutmacher aus Stoff werden zum Anlass des Int. Frauentages an die übergeben.

Mehr als Bau: GP setzt auf Mitarbeitergesundheit und Teamspirit

GP investiert in neue Technologie von oben!02.02.2024

Die Maschinentechnik testete die neueste Mavic 3E. Technischer Fortschritt und die aktuellste Zertifizierung treiben die Digitalisierung der Baustelle voran.

GP investiert in neue Technologie von oben!

Steinbruch Piesberg, der 30.08.2023: Die GP Papenburg Maschinentechnik GmbH testete gemeinsam mit der G-Tec Positioning GmbH die neueste Drohne Mavic 3E. Diese ist mit der aktuellsten Zertifizierungsklasse C2 zertifiziert und erlaubt somit ab dem 01.01.2024 weiterhin den Betrieb in der offenen Kategorie.

Die technische Weiterentwicklung der Drohne machen das Befliegen großer Flächen in kürzester Zeit möglich. Hinzu kommen eine verbesserte Auflösung der Kamera, sowohl im Vermessungsbereich als auch für Fotoaufnahmen, und die Handlichkeit der Drohne, welche für diese Investition sprechen.

DJI Mavic 3E

DJI Mavic 3E

GP investiert in neue Technologie von oben!

GP investiert in neue Technologie von oben!

GP – Kennenlernen12.03.2024

Wenn es um die eigene berufliche Zukunft geht, hast Du die Qual der Wahl. Wer wissen möchte, was die GP Gruppe alles macht und wie es im Unternehmen aussieht, hat viele Möglichkeiten, GP kennenzulernen. Bei uns geht mehr als nur Praktikum!

GP – Kennenlernen

Über 30 Ausbildungsberufe und duale Studiengänge bietet die GP Gruppe jungen Menschen – da sind viele spannende Berufe dabei. Was genau das Arbeiten bei uns bedeutet, was der Berufsalltag mit sich bringt und welche Tätigkeiten dazu gehören, kann man bei Praktika in ganz unterschiedlichen Bereichen entdecken.

Ein kaufmännisches oder gewerblich-technisches Praktikum für Schüler:innen und Studierende bietet interessante Einblicke und gute Kontaktmöglichkeiten zu Ausbilder:innen oder Azubis.

Selbstverständlich bieten wir Schulleiter:innen und Lehrkräften ebenfalls mehrtägige Lehrerbetriebspraktika an. Manchmal reicht aber auch ein Tag, um einen kurzen Einblick in die Vielfalt der GP Gruppe zu erhalten. Der findet jährlich statt und begeistert immer wieder Hunderte von Schüler:innen. Die Zukunft von jungen Menschen liegt uns am Herzen – deshalb engagieren wir uns zum bundesweiten und am . Neugierig geworden? Lernen Sie uns kennen!

Kontakt | Bereich Praktikum

Bau- und Verwaltungsgesellschaft mbH

Team Ausbildung

Berliner Straße 239, 06112 Halle (Saale)

FON +49 345 5113-417

GP – Kennenlernen

Berufsorientierung – GP unterwegs05.09.2023

Ob in Schulen oder Unternehmen, auf Messen und Veranstaltungen oder in Netzwerken – wir sind dabei, machen mit und engagieren uns für die Fachkräfte von morgen. Was wir alles machen? Schauen Sie selbst…

Berufsorientierung – GP unterwegs

Projekttag an der Schule? Praxisnaher Unterricht? Dafür gibt es bei der GP Gruppe verschiedene Angebote. Beim entdecken Schüler:innen spielerisch ihre individuellen Stärken und erfahren, was für den Einstieg in das Arbeitsleben relevant ist.

Der für die Jahrgangsstufe 7 und der , der für Schüler:innen ab der Klasse 9 geeignet ist, sind spielerische Angebote für den Unterricht. Der GP Wissensbaustein Medien kann hervorragend im Rahmen einer Projektwoche zur Suchtprävention eingesetzt werden.

Auf verschiedenen regionalen sind wir für Jugendliche und deren Eltern, für Lehrkräfte und auch Bildungsträger da, geben Einblicke in die GP Gruppe und die berufliche Perspektive bei uns. Gern beantworten wir Fragen rund um Praktika, Ausbildung, Duales Studium und geben Tipps für die Bewerbung.

Die Förderung von Kooperationen zwischen Schulen und Unternehmen, gute Berufsorientierung, die Begeisterung für MINT sowie spannende Projekte zur ökonomischen und digitalen Bildung – dafür engagiert sich die GP Gruppe auf Bundesebene im und auf Landesebene im .

Im regionalen organisieren die Mitwirkenden regelmäßige Veranstaltungen für Schüler:innen, Lehrkräfte und Unternehmen, wie den LIEBLINGSTAG, das Schulleiter-Forum „Schule trifft Unternehmen“, die Lehrerweiterbildung „Praxis erleben – Bildung gestalten“ und das Online-Unternehmer-Treffen.

Berufsorientierung – GP unterwegs

Das digitale Cockpit - ein Erfahrungsbericht10.01.2024

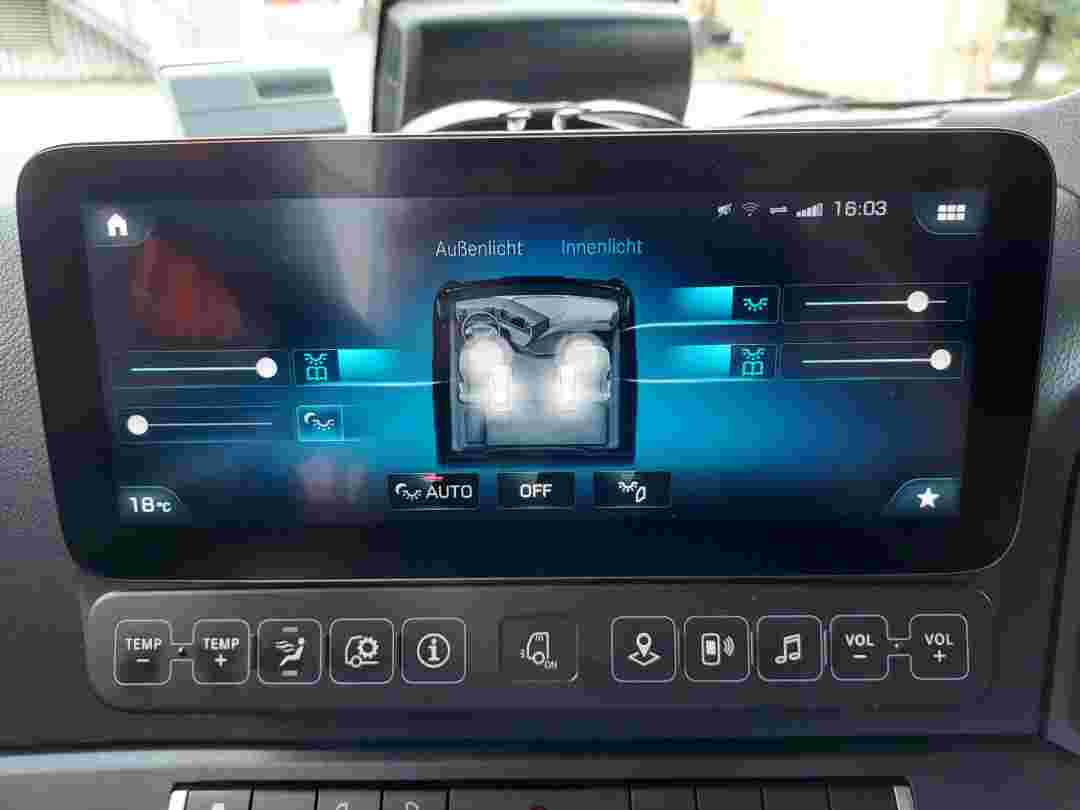

Der Beruf des Kraftfahrers (m/w/d) ist einem stetigen Wandel unterlegen - auch vor dem Cockpit macht die Digitalisierung nicht halt. Das klassische Armaturenbrett wird zur Schaltzentrale.

Das digitale Cockpit - ein Erfahrungsbericht

"Ganz schön bunt", war mein erster Eindruck des Cockpits, als mich mein Kollege Peter S. in "seinen" neuen Mercedes Actros einlud, um über die Digitalisierung seines Arbeitsplatzes zu sprechen.

Peter S. fährt seit vielen Jahren Silozüge bei der GP Günter Papenburg AG. "Wir sind direkt in die Lieferketten im Baustoffbereich eingebunden, da kommt es auf Zuverlässigkeit an. Das gilt aber nicht nur für die Technik", fügt er schmunzelnd hinzu. "OK, das habe ich verstanden", grinse ich zurück.

Das neue, digitale Cockpit sei schon eine Umstellung gewesen, "da musste ich mich erst zurechtfinden", so der erfahrene Kraftfahrer. Viele klassische Schalter wurden durch virtuelle Schalter und Schieberegler ersetzt. Die Menüführung geht über mehrere Ebenen, "ist aber logisch aufgebaut, wenn man es einmal verstanden hat. Das Diagnosesystem hilft bei der Abfahrtskontrolle und bei drohenden technischen Problemen. Da kann ich dann schnell mit meiner Disposition Rücksprache halten, bevor es zu einem Ausfall kommt".

Begeistert zeigte sich Peter S. von den Assistenzsystemen der neuesten Generation. Das sein "Actros" auch das Höhenprofil der Fahrtstrecke "kennt" und rechtzeitig schaltet, war ihm bereits geläufig. Neu war allerdings, dass seine Sattelzugmaschine auch Kurven erkennen kann und die Geschwindigkeit automatisch anpasst, wenn er es als Fahrer nicht selber oder nicht rechtzeitig tut. "Ein echtes Plus an Sicherheit", findet Peter.

Auch die übrigen Assistenzsysteme, wie Abstandsregeltempomat, Notbremsassistent, Schildererkennung, Spurhalteassistent und natürlich den Abbiegeassistenten möchte Peter S. nicht missen.

"Das beste Assistenzsystem ist aber die gegenseitige Rücksichtnahme im Straßenverkehr. Da hapert es in der Praxis zuweilen noch", grinst mein Kollege noch zum Abschied. Vielen Dank, Peter, und gute Fahrt!

Das digitale Cockpit - ein Erfahrungsbericht

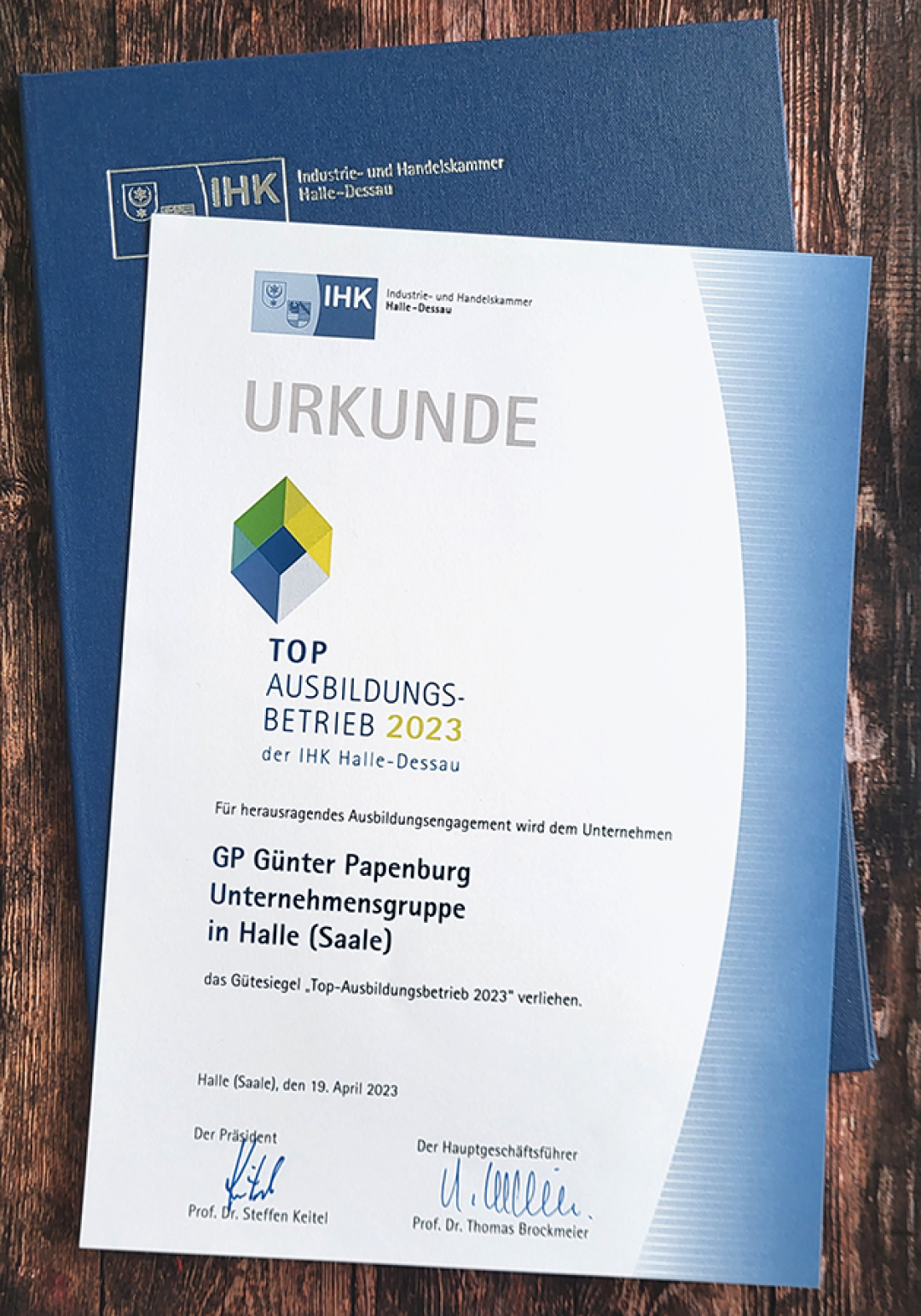

GP „Top-Ausbildungsbetrieb“ 202323.02.2024

Bereits zum 11. Mal zeichnet die IHK Halle-Dessau den „Top-Ausbildungsbetrieb“ aus. Wir sind stolz, dass der GP Gruppe die Auszeichnung 2023 wieder verliehen wurde. Die IHK würdigt mit dieser Auszeichnung jene Betriebe, die eine qualitativ hochwertige Ausbildung bieten und sich besonders für Berufsorientierung und Fachkräfteentwicklung einsetzen.

GP „Top-Ausbildungsbetrieb“ 2023

Bereits zum 11. Mal zeichnet die Industrie- und Handelskammer (IHK) Halle-Dessau den „Top-Ausbildungsbetrieb“ aus. Die IHK würdigt mit dieser Auszeichnung jene Betriebe, die eine qualitativ hochwertige Ausbildung bieten und sich besonders für Berufsorientierung und Fachkräfteentwicklung einsetzen. Wir sind stolz, dass der GP Gruppe die Auszeichnung „Top-Ausbildungsbetrieb“ auch im Jahr 2023 wieder verliehen wurde.

Insgesamt erhielt die GP Gruppe diese besondere Anerkennung bereits zum 6. Mal.

Die Ehrung ist zugleich Ansporn, unseren Auszubildenden im kaufmännischen und gewerblichen Bereich auch weiterhin eine qualifizierte Ausbildung zu bieten und sie in der Entwicklung ihrer persönlichen und sozialen Kompetenzen zu fördern.

Dabei legen wir großen Wert darauf, dass unseren Auszubildenden nach einer angemessenen und individuellen Einarbeitung in den Büros, auf den Baustellen und unseren Werken auch eigenverantwortliche Aufgaben übertragen werden. Neben der schulischen und praktischen Kenntnisvermittlung wollen wir stets die Attraktivität unserer Ausbildung mit frischen Ideen und vielfältigen Aufgaben erhöhen. So übernehmen die Auszubildenden eigene Projekte, helfen bei der Öffentlichkeitsarbeit auf Events und Messen und haben die Möglichkeit zu einem Auslandsaufenthalt. Derzeit befinden sich im mitteldeutschem Raum 146 junge Menschen in der Ausbildung, die der Gewinnung von motivierten Nachwuchskräften dient.

Damit unsere Ausbildung weiter an Qualität gewinnt, werden seit Dezember 2015 2x jährlich Ausbilder-Foren mit externem Input durchgeführt > Diversity Training, Entwicklung und Stärkung der Personal- und Sozialkompetenz, Wertschätzende Gesprächsführung, Feedbackgespräche erfolgreich führen, Digitalisierung in der Ausbildung, Nachhaltigkeit.